Echizen Uchihamono, a traditional craft of Echizen City, Fukui Prefecture, is a world-class product. The knives, which combine traditional fire-making forging techniques with modern design, have been highly acclaimed and are inundated with orders from famous chefs in Japan and abroad. However, until 50 years ago, the entire production area had declined to such an extent that its current prosperity was unimaginable, and even its survival was in jeopardy, but one thing led to a dramatic revival. The man behind this dramatic revival is Katsuyasu Kamo of Kamo Cutlery.

The one and only “vegetable harvesting knife”

Kamo Cutlery is located in the Takefu Knife Village, southeast of Echizen City. The facility will be renovated in 2020. The modern, equilateral triangular building is impressive and does not evoke the image of “cutlery. Takefu Knife Village is a joint workshop of 13 cutlery companies that produce Echizen hammered blades, and in addition to offering the rare experience of forging hammered blades, it also has a workshop tour and a direct sales shop for kitchen knives and knives.

A key player in the revival of the production area

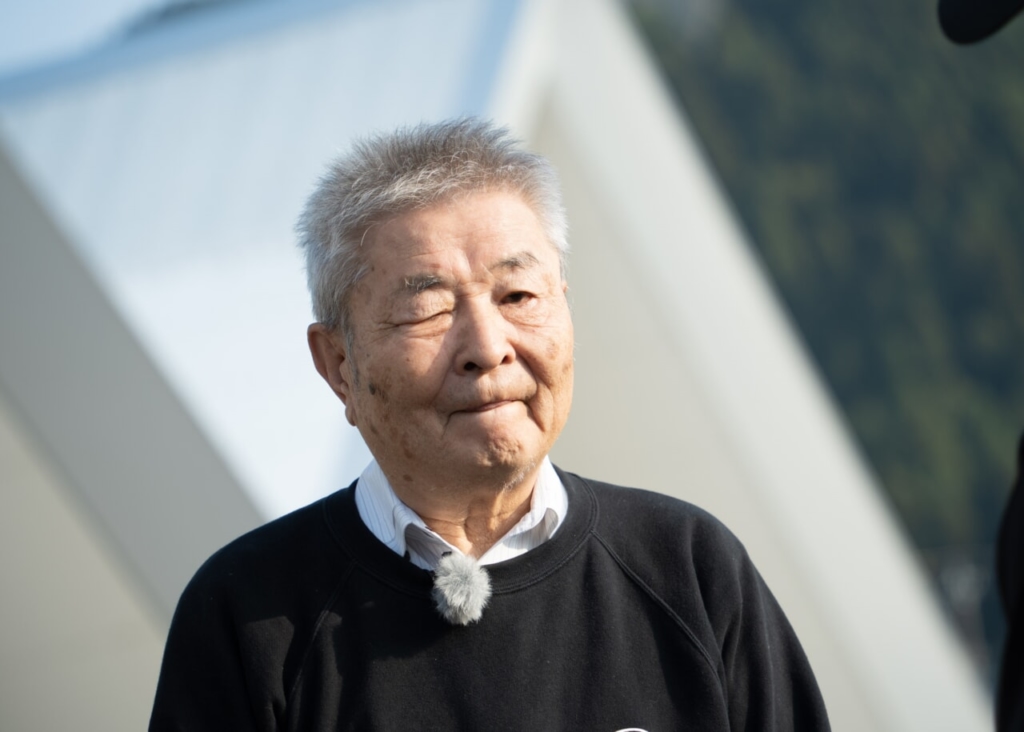

Born in 1941, Mr. Kamo, who made a major contribution to the establishment of Takefu Knife Village, was certified as a traditional craftsman in 2008 and has served as the first chairman of the Takefu Knife Village Cooperative since the establishment of the facility. Mr. Kamo’s history as a craftsman is also the history of traditional crafts, from their decline to their revival to their current prosperity.

The Decline of Vegetable Cutting Knives

Mr. Kamo, born in Echizen City, dropped out of a local high school to help his father, a knife maker of vegetable cutting knives, and became a hammered knife craftsman in 1956. While apprenticing under his father, he mastered the “hi-zukuri forging two-ply spreading” technique, which is unique to this region, in which two steel blades are layered and stretched thin. The blade of the vegetable knife finished with this technique is thin. The blade is so thin that it is extremely sharp, and until the 1970s it sold like hotcakes, as Mr. Kamo himself says. However, with the advent of santoku knives, which can be used not only for cutting vegetables but also meat and fish, and stainless steel knives, which are resistant to rust, the demand for this product, which has few uses, gradually declined.

Knives that Make Harvesting Vegetables Easy

Sales of vegetable cutting knives had been declining with the changing times, but the sharpness of the double-edged blade was still highly regarded.

Mr. Kamo, a vegetable farmer in Nagano Prefecture, was wondering if he could make a new kitchen knife using this technology. A fellow skier who ran a vegetable farm in Nagano Prefecture introduced him to an agricultural cooperative in the prefecture, suggesting that he could propose a vegetable knife to a place that would meet the demand for such knives.

When we visited him all the way there, we learned that growers cut several thousand plants of cabbage and other vegetables a day, and that it is not unusual for them to get kenshoitis. Realizing that there might be a demand for a knife that could be used differently from the conventional way, but which would make harvesting vegetables easier, Mr. Kamo worked with vegetable farmers to develop one, and in 1975, they completed the “Vegetable Harvesting Knife.

Various innovations to help farmers

The vegetable harvesting knife has a blade all the way to the tip, as shown in the photo above, so that the tip of the blade can cut the core of cabbage or Chinese cabbage by pressing lightly on it. The blade is slightly warped to prevent damage to the leaves when harvesting. Farmers who have used the machine have highly praised it, saying that it has reduced the burden of harvesting and improved the quality of the vegetables they ship. Furthermore, after hearing that farmers sometimes lose sight of their knives in the field while farming or injure themselves by stepping on them unexpectedly, Mr. Kamo devised the red handle so that the knife would stand out. Gradually, the distinctive red handle came to be known as “Kamo-red,” and became synonymous with Kamo-san’s harvesting knives.

Kitchen Knives Loved in Vegetable Growing Regions Nationwide

Convinced that he could create knives that were truly needed only by working directly with farmers, the users of his products, Mr. Kamo went on to visit vegetable-growing regions such as Chiba, Ibaraki, Iwate, and Hokkaido. In addition to knives specially designed for harvesting broccoli, which at the time was being cultivated by an increasing number of farmers, he also developed a left-handed harvesting knife and a lightweight model that is easy for women to use, which he sold to agricultural cooperatives throughout the country. He regularly visited the users of his knives and performed maintenance such as resharpening and repairing handles. Word of Kamo’s approach to producers and the sharpness of his Echizen Uchihamono knives spread by word of mouth, and his vegetable harvesting knives are now used in more than 30 locations throughout Japan.

Currently, Mr. Kamo’s vegetable harvesting knives are lined up by vegetable, such as cabbage, lettuce, celery, broccoli, Chinese cabbage, green onion leaves, Chinese cabbage, and radish leaves, each with a different shape and blade length. These are available in more than 50 varieties, with approximately 6,000 sold annually.

To not erase 700 years of tradition

Mr. Kamo’s vegetable harvesting knives are also linked to the origin of Echizen Uchihamono. About 700 years ago, a Kyoto swordsmith named “Chiyotsuru Kuniyasu” moved to Echizen in search of a suitable place to make swords, and in addition to swords, he also made sickles for nearby farmers, which he called “Echizen sickles,” and this is believed to be the origin of the name. Since then, Echizen became a major producer of agricultural cutlery, and these products spread in the form of “peddling” throughout the country.

Peddler who spread Echizen sickles throughout Japan

The peddlers were lacquer shovel craftsmen who traveled around the country in search of lacquer for Echizen lacquerware, a traditional craft also known in Fukui Prefecture. They sold their cutlery to farmers wherever they went and brought back orders for sickles from all over the country, and Echizen sickles are said to have been the nation’s largest producer from the middle of the Edo period until the Meiji period.

The sharpness of the Echizen sickle resides

However, during the period of high economic growth in the Showa era (1926-1989), the mechanization of agriculture and forestry advanced, and the demand for sickles continued to decline. Along with this, sickle producers were forced out of business one after another.

On the other hand, mechanization of vegetable crops, which are more diverse in variety and shape than rice and are often harvested on slopes or in confined spaces, lagged behind. Even today, the harvesting of vegetables such as Chinese cabbage, lettuce, and broccoli is still largely unmechanized and done mainly by hand. Mr. Kamo found a way for Echizen Uchihamono to survive in knives specially designed for harvesting vegetables, and like the lacquer shovel craftsmen of the past, he personally went around the country visiting farmers to promote the harvesting knives. The high quality of Echizen Uchihamono, which had become known to farmers nationwide through the sickle, was once again recognized through vegetable harvesting knives.

Meet the World’s Leading Designers

Mr. Kamo revived a traditional craft that had been in decline for some time as vegetable harvesting knives, but when he looked at the situation in the region as a whole, the situation had not changed much, and the region was facing severe price competition from inexpensive cutlery products.

If nothing is done, 700 years of history will disappear.

In 1973, Mr. Kamo and 10 other successors of cutlery companies in the region, who felt a sense of crisis about the future of Echizen hammered cutlery, got together and launched a study group to consider these issues. The group began its activities with a focus on branding Echizen hammered blades to break away from price competition. Then, things started to move quickly when the Industrial Research Institute, with whom they had a relationship, introduced them to Kazuo Kawasaki, a world-renowned designer in the field of product and industrial design who hailed from Fukui Prefecture.

We immediately explained to Mr. Kawasaki about the activities being promoted by the association and succeeded in gaining his approval. Mr. Kawasaki proposed the development of new products from a designer’s point of view, incorporating modern design concepts while preserving the basics of traditional Echizen hammered blades. However, Mr. Kamo and his team were puzzled by the shape of the knife, which they had never seen before.

The most important reason was that they wondered if it was possible to reproduce the shape by handwork of craftsmen.

If it were just a shape, it could be done by press working,” said Kamo. However, the value of Echizen Uchihamono lies in creating the form using the traditional fire forging technique.” While struggling with this question, he finally developed new products, including an all-purpose all-stainless steel kitchen knife with an integrated blade and handle, through repeated trial and error. This was the beginning of an explosive hit.

Birth of Takefu Knife Village

In 1983, the company finally completed a kitchen knife with a novel design that would be the future of Echizen Uchihamono. He named the brand “Takefu Knife” and held an exhibition at a gallery in Tokyo, which was surprisingly well received. Riding the momentum of this success, the company vigorously held exhibitions throughout Japan, including a very successful one in New York in 1986. This gave the members of the study group the confidence that “anything can be accomplished if we work together,” and gradually “the branding of kitchen knives got on track. The next step was to create a place that would attract people from outside of Echizen to Echizen Uchihamono.

In 1993, Mr. Kamo and his colleagues invested 30 million yen per person to complete the “Takefu Knife Village,” a joint workshop. This created the advantages of a workshop that was widely accessible and craftspeople could share expensive processing machines. But above all, the most significant impact was that discussions among everyone expanded their knowledge and led to the development of new products. At the time, we were all in debt. It was a big gamble, but we were able to make the decision because we absolutely needed a base to promote Echizen Uchihamono to the world. As a result, I think the creation of the knife village led to the revival of the production area.”

Echizen Uchihamono becomes a world brand

After 2010, Echizen Uchihamono knives began to receive orders from all over the world, as their sharpness and design quality were highly acclaimed by famous chefs overseas. Today, 70-80% of the knives produced by Takefu Knife Village are destined for overseas markets. The workshop, which initially had only 10 craftsmen, including Mr. Kamo, now has more than 40 craftsmen honing their skills.

Now, the production area is sailing smoothly,” says Mr. Kamo. Producers are now responsible for pricing, and the number of expensive knives is increasing. In this age of dreams, we want to protect the Echizen Uchihamono brand by not cutting corners and by respecting the basics of proper craftsmanship,” says Mr. Kamo. Under his leadership, successors are growing steadily, and not only people from within the prefecture but also young people from outside the prefecture are training hard, making the former environment of working under bare light bulbs seem a lie.

The spirit of Mr. Kamo and his colleagues, who have continued to take on the challenge of reviving a traditional craft, will be passed on to the younger generation, and a new page will be carved in the history of Echizen hammered blades.