Tsuruga Kombu Honmachi Honten” runs a processing industry of ‘oboro kombu’, a specialty of Fukui Prefecture, in Tsuruga City, Fukui Prefecture.

From the middle of the Edo period to the Meiji period, Tsuruga prospered as a port of call for “Kitamae Senpaku” (Kitamae ships),

The company carefully selects the finest kelp and produces “oboro kelp” of exquisite thickness that only Tsuruga kelp craftsmen can produce.

It is a delicacy that is sure to please gourmets from all over the country.

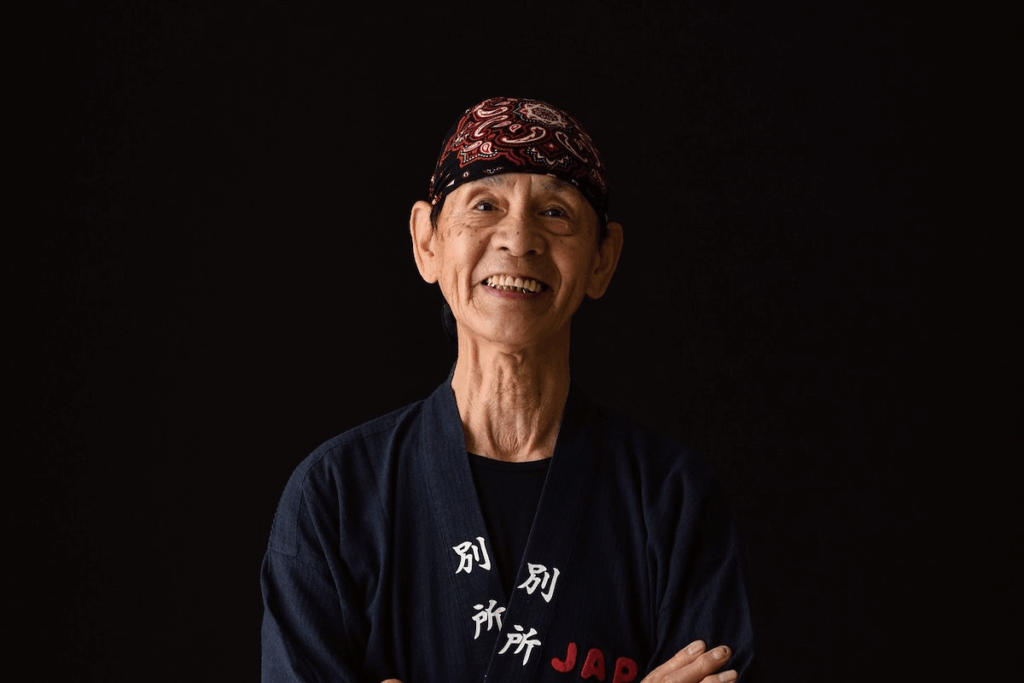

Tsuruga Kombu” is a processing company of specialty ‘oboro kombu’ in Tsuruga City, Fukui Prefecture. Akio Bessho, a handmade kelp craftsman, was selected as a “Contemporary Master Craftsman” in 2020 for his outstanding skills. We interviewed the specialist who has been working in this field for 63 years and knows everything about kelp about the charm of oboro kelp and the work of a handmade kelp craftsman.

Oboro kelp, a local industry representative of Tsuruga

Tsuruga City, located in the Reinan region of southwestern Fukui Prefecture, is a port city facing Tsuruga Bay on the Sea of Japan and once flourished as a port of call for “Kitamaebune” ships. Kitamaebune” refers to a group of merchant ships that operated between Hokkaido and Osaka from the mid-Edo period to the Meiji period. They linked Hokkaido and Osaka, buying and selling goods around the Sea of Japan. At Tsuruga, one of the ports of call, kelp and herring brought from Hokkaido were unloaded and stored in warehouses, and many of them made their fortunes as kelp dealers. Kelp was mainly transported to Kyoto and other parts of the Kansai region, while herring was transported to various parts of western Japan not only for eating, but also as fertilizer for growing cotton and other crops.

Tsuruga prospered as a major kelp accumulation area, and kelp shops lined the streets, attracting craftsmen who processed kelp, which grew into a local industry. The “Saiku Kombu” used in ceremonies and cooking, and the “Oboro Kombu” and “Tororo Kombu” made of thinly shaved kombu appeared and became popular in Kyoto, Osaka, and other cities. It is believed that oboro kelp and tororo kelp were born at about the same time, and even today, when the center of distribution has shifted to Osaka, processing of oboro kelp is still active in Tsuruga, which accounts for more than 80% of the nation’s production.

Tradition of “oboro kelp” spun by artisans

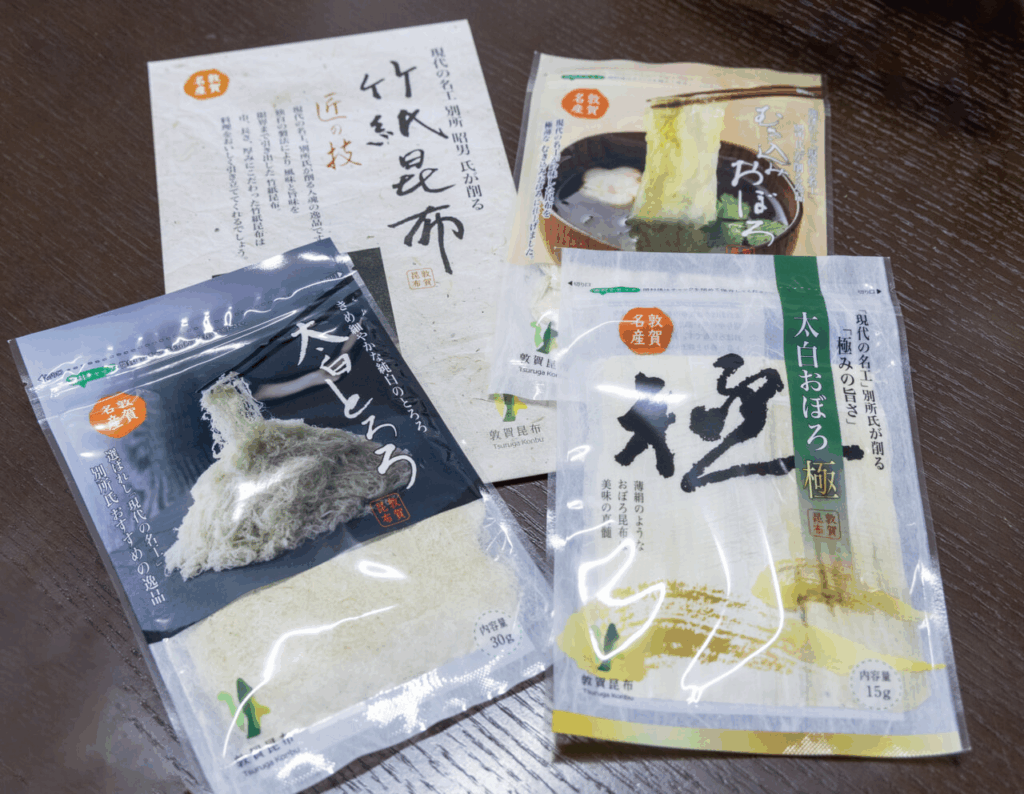

Tsuruga Kombu was founded in 2017 by the current head of Tsuruga Kombu, Takayuki Morita, who has a long career in sales and purchasing at a long-established kombu shop in Fukui Prefecture. As one of the 20 or so kelp processors in Tsuruga, Tsuruga Kelp mainly sells oboro kelp as well as dashi kelp and other products. In addition to hiring handmade kelp craftsmen as employees, the company’s main business is to purchase oboro kelp from individual handmade kelp craftsmen and distribute it to kelp specialty stores. There are many artisans in Tsuruga who shave kelp at home, and in the past, Mr. Bessho also continued to work privately. However, he has joined the company to take on the Tsuruga kelp business because he shares Mr. Morita’s philosophy of preserving the traditional local industry of oboro kelp and aiming to become a company that can contribute to the local community.

Craftsmen shave each piece by hand.

As Mr. Bessho says, “Generally speaking, people may be more familiar with tororo kombu than oboro kombu,” both oboro kombu and tororo kombu are thinly processed kombu products, and the differences between them are not well known.

The difference between oboro kelp and tororo kelp lies in the way it is shaved. Tororo kelp is made by layering and pressing several sheets of kelp and shaving them into a large block. The sides of the layered kelp are shaved, resulting in a fine shape. Tororo kelp is often sold in supermarkets because mechanization has made it possible to shave a large amount of kelp in a short period of time. Today, even in Osaka, a major kelp consumption area, tororo kelp is commonly available.

On the other hand, for oboro kelp, a craftsman shaves one piece of kelp from the surface in a thin and wide range. Since the quality of the kelp is directly reflected, clean kelp with few blemishes is used. Compared to Tororo kelp, which is shaved by machine, the amount that a craftsman can shave is very small. Therefore, the price of oboro kelp is higher, and according to Mr. Morita, it can cost twice as much as tororo kelp, depending on the type of kelp.

Tororo kelp has a fluffy texture and the flavor of the kelp spreads gradually in the mouth. On the other hand, oboro kelp is firm in texture and the flavor of kelp can be tasted directly.

Oboro kelp is produced in Hokkaido, Tohoku, and Osaka, but Tsuruga has a particularly strong reputation for its handmade technique. It is precisely because the Tsuruga region has preserved the “craftsmanship” of carefully thinly shaving each piece of high-quality kelp by hand that the gem of oboro kelp has survived to this day.

Using up all the kelp

How did oboro kelp come about in the first place? In the Edo period (1603-1867), some of the kelp brought to Tsuruga by the Kitamae Ship had developed mold during the process of drying and maturing. The kelp was soaked in vinegar to soften it, and when the mold-free surface was scraped with a piece of glass, the taste was so good that it was commercialized as oboro kelp.

Even today, the only ingredients for oboro kombu are kombu and vinegar. The kelp is very hard, so the craftsmen soak it in vinegar to soften it and make it easier to shave before shaving it into oboro kelp. Tsuruga Kombu” offers four types of products, each with a different name depending on the part of the kelp to be shaved.

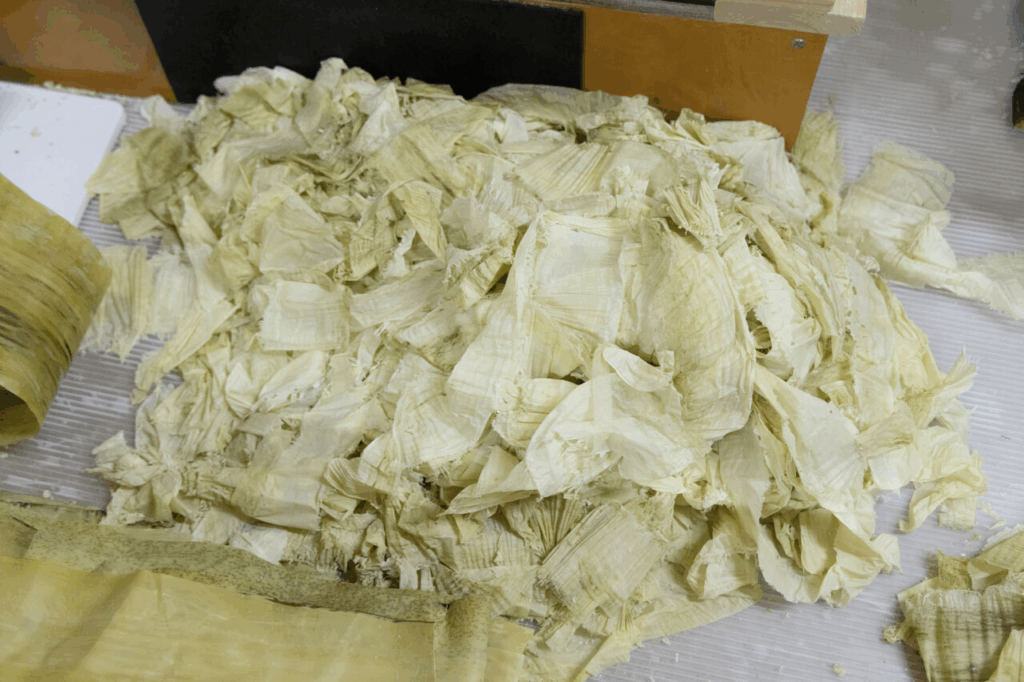

First, both ends of the kelp soaked in vinegar are cut off to make the shape uniform, and then the kelp is shaved from the surface. Kuro oboro” is made by shaving the black part of the kelp surface and is characterized by its strong sour taste. The “Mukikomi Oboro” is a mixture of the black part of the kelp surface and the white part inside, and has just the right amount of saltiness and acidity. Taihaku Oboro” is made by shaving only the white part of the kelp close to the core, and is considered to be the best quality kelp. Shiroita Kombu” is made by trimming the core of ‘Oboro Kombu’ after shaving it. Because of its thickness, it is often used to wrap ingredients. A typical example is the thin, clear kelp at the top of batella and saba-zushi.

Kurooboro,” or ‘black kelp,’ which is closer to the surface of the kelp, allows for a direct sensation of saltiness, acidity, and umami flavor. As you move closer to the core of the kelp, you can enjoy the refined flavor of the kelp itself, which enhances the dishes to which it is added. Use a whole piece of kelp. Mr. Bessho and other handmade kelp artisans preserve this uniquely beautiful Japanese food culture.

0.01mm and 0.1mm. The art of shaving to the finest thickness

The thickness of the oboro kelp shaved by Mr. Bessho is only 0.01 mm. It has been commercialized by Tsuruga Kombu under the name of “Taihaku Oboro Kiwami,” and was the reason Mr. Bessho was awarded the “Contemporary Master Craftsman” award. It is the thinnest kelp ever made, and when you put it in your mouth, it quickly melts on your tongue, and the flavor and aroma of the kelp spreads in your mouth.

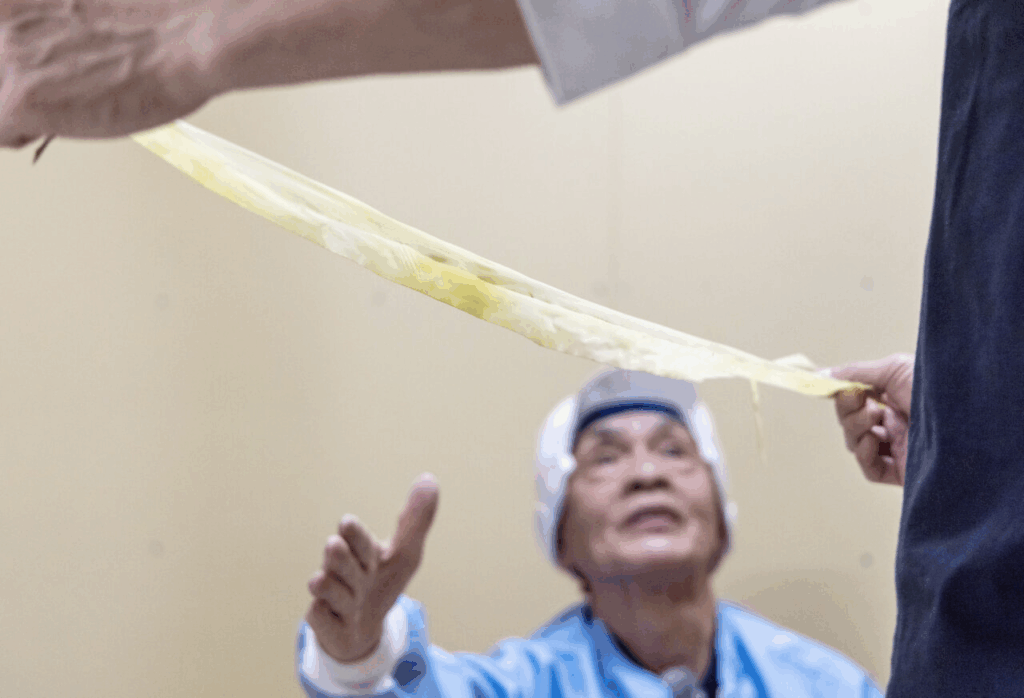

When Mr. Bessho and his staff shave the kelp, they use a special knife. The knife is characterized by its slightly bent blade edge, which is used to shave the kelp by scratching the kelp with the bent edge. Bending the tip of the blade is also an important part of the craftsman’s job. The angle of the blade tip determines the thinness and width of the oboro kelp, so the bending process requires skillful technique.

The knife, which is the life of a handmade kelp craftsman, surprisingly needs to be sharpened once every 30 minutes. The knives used to sharpen the kelp are so thin that they soon lose their ability to sharpen because the kelp no longer catches on the blade, so they are resharpened every 30 minutes to bend the edge of the blade and make it ready. Craftsmen call this bending of the cutting edge of the knife “akita,” and the process of adjusting the angle of the cutting edge is called “akita-tsuki” (putting on akita). Some craftsmen prepare two or three knives, and when the blade weakens, they change the entire knife and resharpen it together.

Sharpening with the “foot,” not the wrist

When shaving kelp, the craftsman sits cross-legged on a special stand and puts only his right foot on the ground. Holding the kelp with his right foot, he pulls the kelp with his left hand and shaves it with a knife held in his right hand. Mr. Bessho says, “If you use your wrist to shave, the kelp will fall apart. If you use your foot instead of your wrist to shave the kelp, it will be uniformly thin,” he said.

The skill of a modern master craftsman is evident in the “Takegami Kombu.

There is a type of kelp that Mr. Bessho says is much more difficult to shave than oboro kelp, which is 0.01 mm thick. It is “chikushi kombu. Chikushi kelp is made by shaving the white part of the kelp near the core to a thickness of 0.1 mm. Mr. Bessho adjusts his breathing and concentration, and while maintaining a uniform thickness of 0.1 mm, he shaves a piece of “Takegami Kombu” of 40 to 50 cm in one go. It is truly a master craftsman’s technique that only Mr. Bessho can perform.

Takegami Kombu” is a top-quality product that is mainly ordered by high-class restaurants, and is used to wrap and steam dishes such as sea bream and cod. The 0.1 mm thickness of “Takegami Kombu” is exquisite because it keeps the kombu from melting when steamed and transfers the flavor of the kombu to the ingredients while making the dish look beautiful.

Mr. Bessho developed “Takegami Kombu” in 1980, and has been shaving it for more than 40 years. Mr. Bessho is the only one in Japan who can still shave “Takegami Kombu,” and efforts have begun to succeed him in order to keep the techniques of this “modern master craftsman” alive.

To keep the tradition of handmade kelp alive

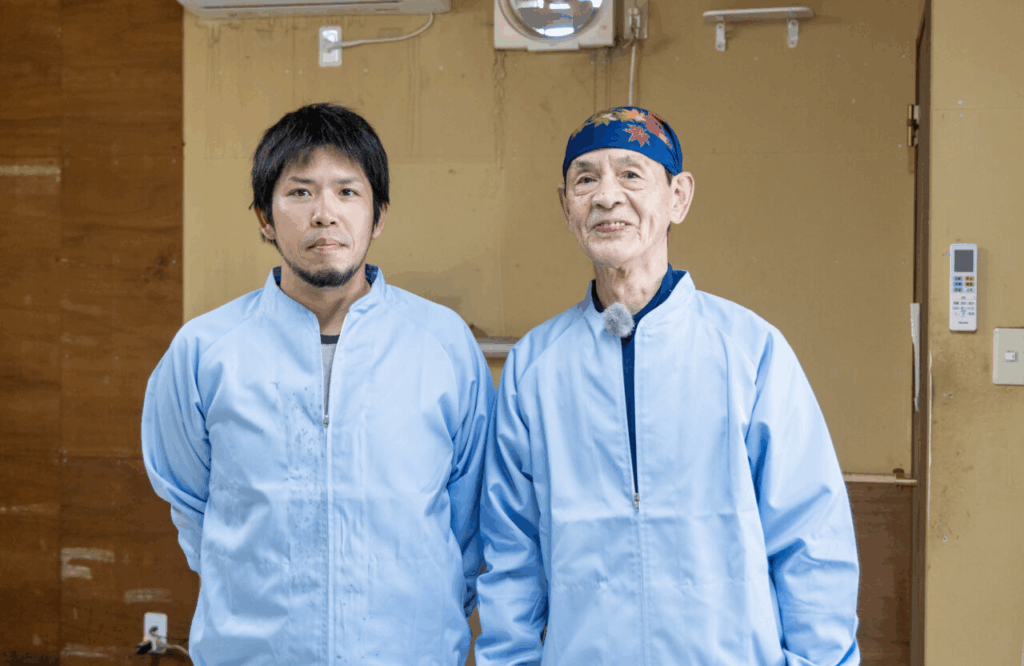

At its peak, the Tsuruga region alone had 500 to 600 handmade kelp craftsmen, but now there are less than 100. The number of artisans is aging. In order to preserve the culture of Tsuruga’s handmade kelp, Bessho says, “I want to focus on training young successors. Mr. Kohei Kawase, who retired from the ironworks where he worked and joined the company as an apprentice “to live my own life.

Kawase shaves 4 to 5 kilograms of oboro kelp a day, not as much as Bessho, who shaves 12 kilograms a day, but under the direct guidance of a master craftsman of rare ability, he is gaining training day by day. I want to make him a full-fledged master in three years,” he says. I want to train him to be a full-fledged master in three years, and I will also take over the technique of “Takegami Kombu,”” says Mr. Bessho.

Since around 2000, Bessho has been giving lectures on kelp eating culture and demonstrating handmade kelp at local schools in Tsuruga City. He also actively travels to events in Tokyo, Yokohama, Kyushu, and other cities to demonstrate handmade kelp. Kawase admired Bessho’s efforts to promote the appeal of handmade kelp.

Spreading Oboro Kombu throughout Japan

Along with training his successors, Mr. Bessho’s dream is to spread the word about Oboro kelp and its food culture throughout Japan. Oboro kelp has a historical background in Osaka, where it was brought from Tsuruga and became popular among the general public in the late Edo period (1603-1868), and spread to Osaka and the rest of the Kansai region. The fact that knives for handmade kelp were made in Sakai, Osaka, which is famous for its cutlery production, is also considered to be a factor in the spread of oboro kelp in the Kansai region.

Makonbu is used for oboro kombu because it is cheaper than Rausu or Rishiri kombu and has a moderate umami flavor compared to kombu used for making broth such as Rausu or Rishiri, making it suitable for eating as is. Originally eaten by the common people, Mr. Bessho hopes that people all over the country, not just in restaurants, will enjoy eating oboro kombu.

The best way to eat it is to roll up a rice ball with oboro kombu, but oboro kombu is also tasty as a snack or with alcohol. It can also be put in a bowl, poured over hot water, and drizzled with soy sauce to make an elegant soup, or topped with udon noodles to enjoy a bit of luxury in a casual way. Mr. Bessho also taught us how to make kombujime, a quick and easy way to wrap sashimi in oboro kombu and wait for the kombu to dissolve. Recently, I found a restaurant in Tokyo that serves shabu-shabu with oboro kelp. In the future, I would like to focus on new ways of eating oboro kombu, not only in Japanese cuisine,” he says.

Mr. Bessho says that in order to increase awareness of oboro kombu, he would like to continue to actively visit events nationwide, taking advantage of his title as a modern master craftsman.

In January 2023, the main Tsuruga Kombu store and store will open in a location about a 10-minute walk from JR Tsuruga Station. At the store, artisans will be stationed to demonstrate handmade kelp. With the birth of a new base where artisans can directly interact with consumers, the appeal of Tsuruga’s oboro kelp is sure to spread steadily.

The craftsmen at Tsuruga Kombu Honmachi have been pursuing “what is delicious oboro kombu” and “what is oboro kombu that makes you confident” and have refined their skills in shaving kombu. Skilled craftsmen shave 12 kilograms of oboro kelp uniformly per day while checking the characteristics of each piece of kelp with their hands. He also adjusts the angle of the blade of the special knife used to shave the kelp, sharpening it frequently to keep it sharp. In order to pass on such skillful techniques and meticulous work, he has been training young craftsmen, and is now aiming to pass on the technique of “Takegami Kombu,” a top quality product that can only be made by a modern master craftsman.