Isesaki City in Gunma Prefecture has long been known as a textile town. In its heyday, Isesaki was so popular that it accounted for half of the nation’s kasuri (patterned fabric) production, but today the kasuri makers have ceased to exist. Sadao Saito of “Kasuri Ryobo Saito” is working to keep the Isesaki kasuri tradition alive by passing it on as a Gunma Prefecture Hometown Traditional Craftsman.

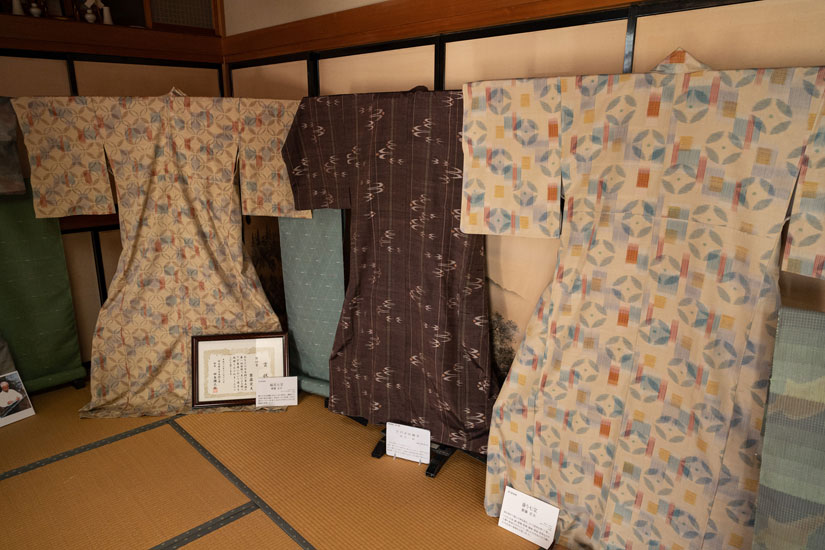

Meisen made in Isesaki City, Gunma Prefecture, a textile town

Isesaki City, Gunma Prefecture, is located in the center of Gunma Prefecture and is rich in nature, connecting Gunma and Saitama prefectures across the Tone River. The city flourished as a sericultural area and has a long history of textile production, with textiles dating back to the 6th century excavated from an ancient burial mound.

The Isesaki kasuri, a simple yet chic kasuri or striped pattern, attracted attention. In the late Meiji period (1868-1912), a textile company was established in Isesaki, and power looms were introduced and some of the textiles were converted to factories. As the needs of the times changed, Isesaki kasuri became known throughout the country as “Isesaki Meisen” and production increased dramatically. From the Taisho era (1912-1926) to the early Showa era (1926-1989), “Isesaki Meisen” was so popular that one out of every ten Japanese women was said to wear it.

However, the times changed from Japanese to Western-style clothing. As the lifestyle of the Japanese people changed, production decreased and the number of producers also declined. Today, there are no more factories producing Isesaki kasuri. Sadao Saito of “Kasuri Workshop Saito” was so concerned about the situation that he decided to preserve the traditional technique of Isesaki kasuri.

One-man operation to preserve the traditional Isesaki kasuri weaving process.

Saito-san has been in the weaving business since he was a teenager, and at the age of 23, he set out on his own as a craftsman. Soon after becoming an independent weaver, Saito-san began working alone on the complicated Isesaki kasuri process, preserving the traditional technique and teaching it to a wider audience.

The reason for this is because, “In order to increase production volume and quality, the Isesaki kasuri process has been divided into separate operations, and people have been trained in each process to improve their skills. However, with the decline in production, the problem has arisen that if there are no successors in one process, products can no longer be made. He says.

Fearing that Isesaki kasuri would cease to be made, Mr. Saito decided to learn all the techniques of the Isesaki kasuri process, from designing patterns to kukuri (wrapping) and dyeing, and to become a person who can do all the processes to make his products.

While creating Isesaki kasuri, he teaches the techniques of all the processes he has learned to younger generations, and he also offers elementary school students in Isesaki City the opportunity to experience weaving Isesaki kasuri, thereby conveying the history and culture of the region.

Isesaki kasuri is protected by strict definition.

At one time, Isesaki kasuri took the world by storm. Production continued to decline, but fearing that this valuable traditional technique would fall into disuse, the company applied for and received designation as a national traditional handicraft in 1975. This led to the establishment of definitions and rules to clarify the differences between Isesaki kasuri and the kasuri of other regions.

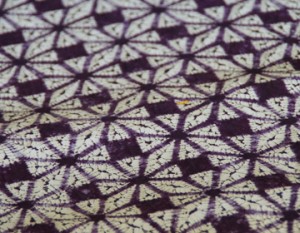

The main definitions of Isesaki kasuri are “yarn-dyed,” “plain weave,” and “silk thread. In the dyeing process, we dye the yarn according to the pattern, using techniques such as kakuri kasuri, itajime kasuri, and nasen (textile printing) to create simple to precise kasuri patterns. The patterns of the dyed kasuri threads are adjusted by hand and woven to match the pattern.

Always striving to express new designs, Mr. Saito experiments by combining two or more techniques.

Weaving is a path of threads that keeps us in touch with the threads.

Mr. Saito says that he has to have perseverance in order to perform more than 10 processes all by himself.

I think you have to be a patient person to do the work of Isesaki Kasuri all by yourself. If you don’t think about what you really want to make and make it yourself, rather than imitating others, you won’t be able to improve your skills.

For example, when you want to make a stole, if you weave in thick yarn, a layer of air is created in the unevenness of the yarn when it is wrapped around the stole, making it warmer. Then, how can we put them in to create originality in terms of both function and design that no one else can imitate? Mr. Saito says the only way to solve this problem is to think about what you want to make in your mind and make it with your own hands.

People can teach you procedures and methods, but the only way to learn the “power” of technical skills is to try it yourself,” he says.

Mr. Saito has designed more than 1,000 kasuri patterns. He has kept all of them as proof that he actually created them with his own hands.

Warp and weft threads weave the vivid patterns

Of the yarn-dyeing techniques that are used to create designs by dying colors in the thread stage before weaving the cloth, Mr. Saito specializes in a technique called kakuri kasuri.

In kakuri kasuri, the part of the yarn not to be dyed is tied up with tape to prevent the color from entering the yarn. By using the warp and weft yarns made from the kasuri threads, the undyed and dyed portions blend together to create a unique pattern that looks as if it has been blurred.

Weaving with warp and weft threads that are both or either made with kasuri yarn and matching the pattern requires a high level of skill and experience.

The technique of dyeing the kasuri threads, and the use of the warp and weft threads and how they are used, create a kasuri expression that cannot be imitated by anyone else.

Mr. Saito spoke of the appeal of kakuri kasuri, and today he is the only person who has inherited the kakuri kasuri technique from Isesaki.

Keeping Isesaki Kasuri alive

The textile industry has declined with the passage of time, but Isesaki kasuri is undoubtedly one of the industries that contributed to the development of this region. Due to its complicated technique and time-consuming production process, the number of makers has decreased and there are hardly any people left who can make Isesaki kasuri using the traditional method. That is why Mr. Saito puts his skills and knowledge into his work and tries to convey Isesaki kasuri to as many people as possible as a valuable traditional craft.

The river flows fast and slow, and there is movement,” he says. I find things in nature that move interesting, and when I come into contact with nature, I am filled with endless ideas. I try to express patterns that are not regular, such as the way the kasuri pattern is blurred.

Not only Isesaki kasuri, but traditional crafts that require time and effort are disappearing in all fields amid today’s emphasis on efficiency. In such an environment, it would be reckless to carry out the time-consuming and labor-intensive process by oneself and pass it on to the next generation. Nevertheless, Mr. Saito’s desire to pass on the traditional techniques that have taken root and developed in the region to as many people as possible is reflected in Isesaki kasuri, a modern-day “meisen” (meisen).