Rice has been an essential part of our food culture since rice cultivation was introduced to Japan about 3,000 years ago. However, after the outbreak of the Sino-Japanese War in 1937, rice, which had been taken for granted, was nearly lost from the tables of the common people for several years. It was during this time of food shortages that “white barley rice,” or “white barley rice,” was born.

Barley Milling Begins in Adversity

Some people still say that seeing black streaks of barley mixed in with white rice makes them feel hungry,” laughs Shigetoshi Nagasawa. Mr. Shigetoshi Nagasawa laughs. Ltd., a manufacturer of barley, glutinous barley, minor grains, and other cereal products. The company’s main product, barley, is rich in soluble and insoluble dietary fiber, which suppresses the rapid rise in blood sugar levels and improves the intestinal environment, and in recent years it has been highly regarded for its health and diet benefits. The company, which has been in business for 83 years and currently holds approximately 60% of the domestic barley production share, began as a rice milling company that produced rice for local farmers.

Let’s make wheat like white rice.

Traditionally, barley was grown mainly as a double crop from fall to spring after the rice harvest was over, but during the war, it came to be grown year-round as a substitute for rice. After World War II ended in 1945, domestic food production and imports gradually recovered. The food crisis began to dissipate, and the distribution of rice gradually began to come back to life. Barley, with its slightly yellowish, black-streaked appearance compared to white rice and the distinctive aroma of oxidized polyphenols, gradually began to be taken off the tables along with the restoration of rice distribution. My grandfather created ‘white barley rice’ as a revival product.

While many barley millers were withdrawing from the market, Shigetaro, who believed that barley was the source of health, invented the “Kyonan-type high-speed cutting machine,” which cuts barley grains in half and removes the black streaks on the surface that serve as transport channels for moisture and nutrients. In 1953, Nagasawa began selling a barley product named “Hakubaku Mai” (white barley rice) with the marketing slogan “barley that looks like white rice.

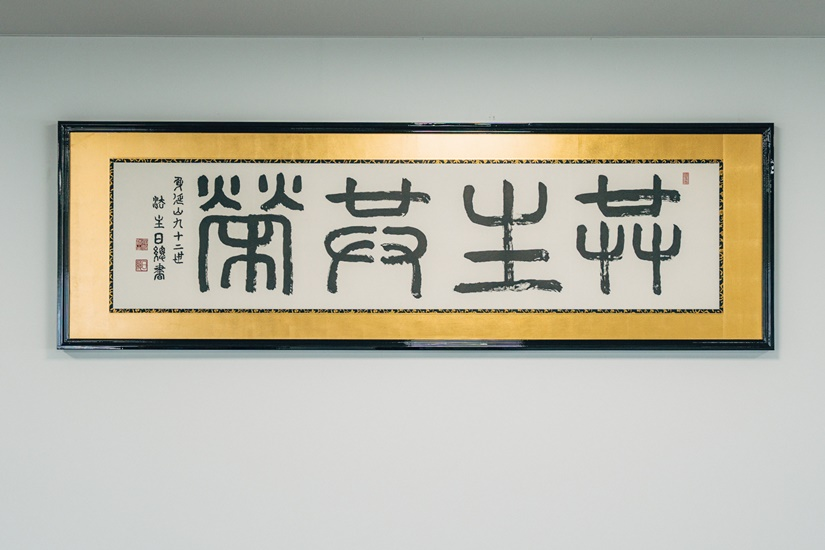

As “Hakubakumai” became popular nationwide as a revolutionary product that overturned conventional wisdom, the company name was changed to “Hakubakumai Co.

After my father took over as the second generation, he worked hard to develop the market for more readily available grain products and dried noodles to further increase sales,” he said.

After the high economic growth period of the 1960s, the company released a series of grain products, such as instant ramen noodles and flour for dumplings, which were readily available at supermarkets and convenience stores. In the 1990s, the company built an udon factory in Australia that uses only organic wheat as its raw material. As a result of this flexible product development that met the needs of the times, Hakubaku steadily increased its business performance, and in 1992, the 45th anniversary of its founding, the company changed its name to Hakubaku Co. Ltd. in 1992, the 45th anniversary of the company’s founding. To date, the company has grown into a barley refining company that has developed more than 100 different products.

We have been offering grain products that are not luxurious like steak, but are delicious and can be eaten every day.

Mr. Nagasawa smiles as he savors the taste of barley.

Not a single particle of foreign matter is allowed in.

In order to obtain safe and delicious barley, Hakuba’s product manufacturing process begins with a quality inspection that covers approximately 400 items. First, the raw materials are inspected again in detail for residual pesticides, moisture content, and any contaminants, and then multiple sorting machines are used to obtain pure barley.

Next, the barley is precisely shaved to ensure uniform cooking. After adjusting the amount of shaving in 0.01mm increments to prevent cracks in the barley grains, the grains are cut in half to remove black streaks, and the shape and color of the barley is then made to resemble that of white rice.

Barley as it is milled absorbs less moisture than white rice and is not cooked well. Therefore, to ensure that the barley is as fluffy as it would be if cooked in white rice at home, it is also pre-processed by heating with steam, cooling, and drying. After these processes, barley is finally ready for simple cooking and tasty eating.

Mr. Nagasawa puts a lot of effort into his words, saying, “We mill barley with the thought, ‘Not even a single piece of foreign matter can get into the barley. The final product is subjected to X-ray and metal detectors to remove any foreign substances, and the taste, aroma, color, and other aspects of quality are also thoroughly checked. This thorough quality control has earned the company high praise from food manufacturers, and in recent years, the company has expanded into new areas, such as supplying raw materials and manufacturing OEM products.

Delivering products to those who really want them

There was a time when sales were sluggish, but in the 2000s, minor grains were introduced on information programs, and the name “Hakubaku” became well known as a health food manufacturer.

In 2016, “glutinous barley” became a breakthrough product as a diet food. Although some major companies entered the market, no one was able to overturn our experience and track record of being at the forefront of the market as a specialized company, precisely because of our core market. In the beverage category, “Mizu-Dashi de Oishii Mugi-cha” and other barley and grain teas increased their market share, further expanding the company’s business.

In March 2023, the company released “Glutinous Barley for White Rice Lovers,” which has had its epidermis scraped away to give it a whiter color that more closely resembles white rice. The β-glucan contained in barley wraps the eaten food into a jelly-like substance and moves it slowly from the stomach to the intestines, so that it takes longer to digest and absorb. This prevents a spike in blood glucose levels, making it less likely to affect weight gain or loss. In addition, the dietary fiber content is 12.9 g, compared to 0.5 g for 100 g of white rice, making it a healthy and guilt-free food. The rice’s elastic texture was also well received and widely recognized as delicious.

However, barley, glutinous barley, and minor grains are consumed by less than 10% of the Japanese population. We believe that we must now propose a new eating habit to the remaining 90%.

For this reason, we have focused on making our products an option for people who are seeking a healthy diet, such as businessmen who eat out frequently, students who are studying hard, and people suffering from lifestyle diseases. The company’s vision for the future is to enter the food service industry and convenience store products, and to further focus on the production of processed foods such as “porridge” and “granola,” which can be easily consumed even by those living alone.

From Yamanashi to the world with our refined ideas

The location next to the Tokyo metropolitan area provides us with favorable conditions for distribution. The high quality water also enhances the quality of our products, and above all, we like our hometown, which is blessed with abundant nature. In recent years, the agricultural products produced in the prefecture and the high quality of water in the Yatsugatake and Mt. Nagasawa reiterates the value of having a production base in Yamanashi Prefecture, saying, “This trend also confirms the high potential of natural resources.

In addition, since 2012, when the Tokyo headquarters was established, the company has strengthened its efforts to recruit human resources in the Tokyo metropolitan area, which has attracted even more talented people in the marketing and product development departments. In response to the current situation, which is also spurring the development of new products, Mr. Nagasawa says, “We would like to spread awareness of barley as a functional food throughout the world while developing new products. Barley is the fifth most produced grain in the world after corn, wheat, rice, and soybeans, yet most of it is used to make beer or to feed livestock. In addition to promoting awareness of barley in Japan, where it is relatively customary to eat barley, he also emphasizes that it is essential to promote the appeal of barley in overseas markets, where food culture is different from that of Japan.

I believe that barley’s label as a “primitive, inedible grain” is the reason why this mission is so dreamy,” he said. No other company in the world struggles so earnestly to make people enjoy eating barley.

Mr. Nagasawa smiles strongly and says that adversity motivates him to keep going. Their polished technology and clean and honest thoughts will convey the “never-ending deliciousness” of grains from Yamanashi to the world.