Making authentic products

Makurazaki is a port town dating back to the mid-Edo period. Among the Japanese prefectures, Kagoshima ranks #1 in the quantity of production of ”katsuobushi” (dried bonito flakes). In this prefecture, Makurazaki has outstandingly thrived with catches of bonitos and production of ”katsuobushi” from early times.

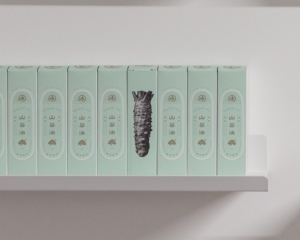

Product names of ”katsuobushi” differ depending on differences in the method of its processing. ”Arabushi” is more common in Kansai and is made by boiling and smoke-drying a bonito. ”Hanakatsuo” or ”katsuokezuribushi” is made by shaving ”arabushi”. ”Karebushi” is more common in Kanto and is made by applying mold fungi to ripen it while subtly dehydrating it. ”Honkarebushi of Makurazaki katsuobushi” is a rich, ripe product with increased inosinic acid, the ”umami” component of bonitos, through the application of mold fungi. This is said to be the highest grade of ”katsuobushi”. ”Honkarebushi” is an authentic product and a local food brand selected by the Japan Food Industry Center. It is proof of a manufacturer that maintains authentic taste with the use of “authentic” and traditional techniques and carefully-selected ingredients such as those unique to the region. More than 300 years are said to have passed since the technique of making ”katsuobushi” was communicated to Makurazaki. ”Honkarebushi of Makurazaki katsuobushi”, certified as an authentic product, reportedly accounts for only 3% of the total quantity of ”katsuobushi” produced in Makurazaki. Wishing to have a glimpse of the katsuobushi certified as authentic, Nakata asked the Cooperative Association of Marine Product Processing Industry, to refer a shop to him.

Each step is performed by hand

Nakata visited Kamiyama Katsuobushi-ten, the shop he had been referred to. Five craftsmen worked silently there. Bonitos successively flow between these craftsmen as they change shape.

Here is a brief explanation of the process of making ”honkarebushi” .

1. Catching and storage: Bonitos are landed at the fishing port of Makurazaki and stored in a large refrigerator to keep them fresh.

2. Delivery: Bonitos are taken out of the minus 25-degree refrigerator and are thawed in circulating water.

3. Cutting raw (1): Cut off the head and belly of a bonito and remove its viscera. Then, make cuts into both sides of the body along the backbone.

4. Cutting raw (2): Cut the dark colored part of the flesh and divide it into the back and belly. Now the bonito has been cut into four.

5. ”Kagodate”: Arrange the cuts of the bonito on a metallic basket named ”nikago”. This step must be performed carefully as it may influence the shape of the final product.

6. ”Shajuku”: Boil the cuts in 90- to 95-degree C hot water for 60 – 90 minutes to carefully skim the scum.

7. ”Honenuki”: Cool the cuts and use a dedicated device to remove bones, subcutaneous fat and dirt.

8. Mending: Insert bonito minces into gaps and cracks of the cut of a bonito to neatly mend its form.

9. Fumigating and drying over direct heat: Burn firewood of hardwood such as oak, sawtooth oak and evergreen oak to dry the cuts of the bonito into blocks. Repeat a cycle of burning firewood four or five times a day and cooling it at night for two or three weeks.

10. Shaving: Shave and remove tar and excess fat from the surface.

11. Applying mold: Dehydrate the blocks and decompose their fat to draw out flavor. Mold can be applied most in the first two or three weeks. Dry them in the sun and apply mold again. Repeat this cycle three or four times to complete ”honkarebushi” .

Highest quality achieved by craftsmen

Nakata experienced the step of cutting a bonito raw. He processed a bonito as Yoshiyuki Kamiyama, a master with a 40-plus-year career in the industry, stood next to him. They clean more than 100 bonitos a day. The work of quickly and neatly cutting many bonitos can only be performed by experienced craftsmen. Nakata experienced the difficulty of the work by partially taking part.

After a brief recess, Nakata also tried to shave completed ”katsuobushi” blocks. He also very closely observed the “craft” of Kamiyama, also one of the few masters of ”satsumagiri” in Japan. Each of the seemingly monotonous steps represents serious commitment by Kamiyama Katsuobushi-ten.