While most of the pearls on the market are cultivated for less than one year and then shipped, Amanari Pearl insists on two-year pearls called “Koshimono” and handles all processing and sales in-house. Mr. Masanori Yamamoto, the chairman of Amanari Pearl, says that the characteristic of Akoya pearls is their beautiful shine, and that the beautiful sea of the Yura Peninsula in Uwajima City is the reason for the high quality of the pearls.

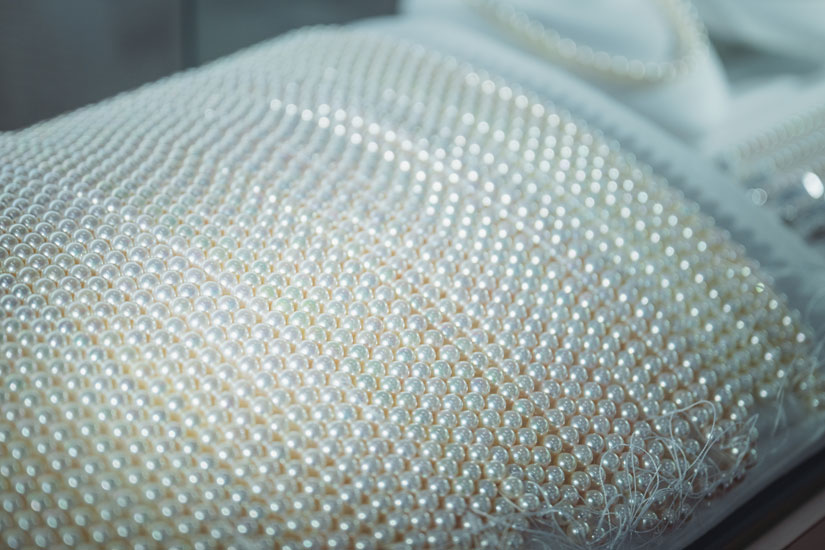

Koshimono pearls with thick, deep, and delicate luster

The waters of the Yura Peninsula, located at the southernmost tip of Uwajima City, Ehime Prefecture, where Amanari Pearl Farm is located, were once said to be unsuitable for pearl cultivation. However, Mr. Yamamoto’s father, together with several colleagues, boldly took up the challenge and succeeded, which is the foundation of Amanari Pearl today.

While most of the pearls on the market are current-year pearls, most of the pearls produced by Amanari Pearl are rare “Koshimono” pearls, which are grown slowly over a period of two years. High-quality pearls produced by the vitality of Akoya oysters and human skill, while benefiting from the abundance of nature in the sea, are processed into jewelry under the company’s own brand while maximizing the individuality of each pearl.

Pearls nurtured by the rich blessings of the sea and human skills

Pearls are natural gemstones produced inside the body of shellfish. When a foreign object enters the body of a certain type of shellfish, such as the Akoya oyster or black-lipped pearl oyster, the shell secretes a nacreous layer to protect itself from the foreign object and encapsulate it, forming a pearl.

Pearl cultivation begins by reducing the activity of the Akoya pearl oyster, which serves as the mother oyster, in preparation for the “nucleation,” in which a nucleus, the core of the pearl, is placed inside the Akoya pearl oyster. The nucleus is placed in the mother oyster, which is a surgery and a huge burden for the oyster, so the oyster is put in a state of sleep by lowering its activity to ease the shock of the nucleus insertion.

Once the shellfish’s activity is sufficiently lowered, the shellfish’s mouth is opened using a special instrument, and the nucleus is quickly and accurately inserted, taking great care not to damage the mother shellfish’s nerves or tissue. This process requires a very high level of skill, and a good or bad nucleus insertion affects the shape of the pearl as well as the damage it will cause.

Once the mother oysters have been cured, they are taken out to the sea, where there are abundant nutrients, and wait for the nucleus to be coiled into the nacreous layer. However, the process is not limited to simply waiting for the nucleus to grow. Daily care and attention is required to maintain an optimal environment for the mother oysters, such as removing barnacles and seaweed that may be attached to the surface of the oysters and impede their growth, changing the depth to which the oysters are submerged in accordance with changes in water temperature, and moving the location of the rafts according to the condition of the oysters. The company also has a strong commitment to the environment. In addition, Amanari Pearl aims to produce high quality pearls in small quantities while minimizing the burden on the natural environment by controlling the amount of cultivation in consideration of the deterioration of the fishing grounds, red tide, disease outbreaks, and water pollution caused by overcrowded cultivation.

Deep brilliance with color is the essence of Akoya pearls

Pearls are evaluated from six main perspectives: size, color, brightness, curl (thickness of the nacreous layer formed around the nucleus), blemishes, and shape. Of these, Mr. Yamamoto says that illumination and curl are the most important factors in evaluating pearls. Teru” refers to the brightness that changes into complex and rich colors, and “kurume” refers to the thickness of the nacreous layer. The thickness of the nacreous layer secreted by the Akoya pearl oyster is closely related to the beauty, transparency, and brilliance of the pearl.

Determining the right timing for raising pearls on the beach is the secret of pearl craftsmanship.

Even though pearls are nurtured for two years, the longer the pearls are nurtured, the lower the survival rate of the mother oysters and the greater the risk of dimples and scars that naturally form on the oysters. According to Mr. Yamamoto, “The timing of the fishing grounds determines the curl, and the timing of the harvesting (removal of pearls from the mother oyster) determines the shine. In winter, Akoya pearls begin to secrete denser layers of nacre, resulting in a beautiful, pale color called “cosmetic curling. Because the water temperature drops early in the season in the Yura Peninsula, the pearl oysters naturally spend more time secreting the nacreous layer, resulting in a thicker nacreous layer. Pearls are removed from the mother oyster at the time when the nacreous coating appears on the top surface, resulting in beautiful pearls with a strong luster. South Sea pearls, such as white and black butterfly pearls, are cultured in warmer waters, so they do not develop a cosmetic coating. The intricate and subtle brilliance of Akoya pearls is unique to Akoya pearls. Pearls are usually weighed and sold in units of “monme,” and some of them are outstanding. We want to add value by processing them into jewelry,” he says.

How to Respond to Changes in the Environment Surrounding Pearl Cultivation

Although the beautiful seas of the Yura Peninsula make it possible to cultivate Koshimono with peace of mind, the ocean environment has become unstable in recent years, partly due to the effects of global warming, and this has caused constant hardship, according to the company. The risk of being wiped out in an instant by a red tide or typhoon is obvious, and the mass mortality of akoya clams in 1995 is still fresh in our minds. We have to keep the ocean in good condition, but we can’t do it by ourselves. In some other regions, akoya clams are no longer growing. Now we are trying to grow mother clams that can withstand global warming.

Another problem is that the number of successors to the shellfish business is decreasing. The decline in the number of mother oyster farmers is a serious problem, because they can concentrate on producing good pearls only if they have people to raise the oysters. He is appealing to his colleagues to think of ways to maintain the industry in parallel with the production of good pearls as pearl farmers.

The Story of Amanari Pearls Spun to the Next Generation and Spreading to the World

There are differences in cultivation techniques among pearl farmers. In the past, they were willing to “protect their own techniques,” but now they are trying to share information and boost the industry as a whole. The population is shrinking and market demand is decreasing, but there are still dedicated fans. In Japan, there is a long-standing culture of grandmothers and mothers giving pearls to their grandchildren and daughters when they come of age. This is a culture that diamonds do not have, and we want to cherish it. We are still working on our own, but I believe that we are recognized in the Tokyo metropolitan area as “pearls from Uwajima” and that our business continues because we have customers who are looking for high-quality pearls.

While cultivating pearls, the company has been seeking ways to sell them on its own, and has established a means of selling them over the Internet in addition to events and promotions. With demand increasing in Asia, they are also looking to create opportunities to sell their pearls overseas. Although each production area has its own goals, Mr. Yamamoto’s desire to produce “Uwajima’s Pearl,” which is particular about the shine and roll of “Koshimono,” and to deliver good products, is strong. He continues to communicate the appeal of pearls in order to protect the Uwajima pearl brand, which has boasted the highest production volume in Japan, and to preserve the pearl industry for the sake of the region.