World-class cutlery by Seki Kenji

Seki City, Gifu Prefecture, is a “cutlery town” where about 300 cutlery-related companies are concentrated.The city is located in the Chuno region in the central part of Gifu Prefecture and is rich in nature, with the Nagara River, Itadori River, and Tsubo River flowing through the city.It is said that two swordsmiths, Motoshige and Kinju, who are considered the founders of Seki smithy, fell in love with this area, which had all the necessary elements for sword making, such as high-quality burnt blade clay, water, and pine charcoal, and moved here and started making Japanese swords.In the Muromachi period (1336-1573), the area produced such master swordsmiths as Magoroku Magoroku, known as “Magoroku of Seki,” and Kanesada Izumi-no-kami, known as “Izumi-no-kami.At its peak, Seki was a major production center with more than 300 swordsmiths, and is known as one of the world’s three major production centers of cutlery along with Solingen in Germany and Sheffield in England.

Seki Kanetsugu Hamono, established over 100 years ago, is a kitchen knife manufacturer founded by a descendant of the swordsmith “Kanetsugu”.There are several “cutlery towns” left in Japan, but Seki is the only production center that has its origins in swordsmithing.We train our knives every day to make them as sharp as Japanese swords,” says Mitsuyasu Kawamura, president of the company.In fact, Japanese food has become popular worldwide in recent years, and Japanese kitchen knives have gained a growing reputation around the world as a result.The reputation of Japanese kitchen knives as the most suitable knives for cutting Japanese foods has spread, and now about 30% of Seki Kanetsugu Knives’ sales come from developed countries overseas, including the United States and Europe.

To become a knife needed by many people

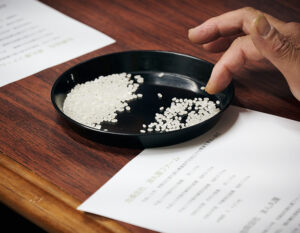

The distinctive feature of Seki Kenji Knives’ kitchen knives is the cross-section called a “clam shell blade.This technique is also used in the 100th anniversary model of “Zuigumo,” a special cutlery knife.According to Kawamura, there are two theories of how a kitchen knife can cut: the “slope theory” and the “sawing theory,” and Seki Kanetsugu Knives produces products that reflect the characteristics of each.The former theory states that a proper amount of warping allows knives to cut objects like Japanese swords, which are warped to produce a sharp edge.The latter theory is that cutting objects is achieved by moving the blade back and forth like a saw.The craftsmen led by Mr. Kawamura pursue the possibilities of knives based on the principles of the Japanese sword and fuse them with modern technology to create knives loved by chefs around the world.

He also says that hints for developing new products can be found in everyday life.I made the ‘Nami’ steak knife because I love steak (laughs).I thought that if I had a knife that could quickly cut through tough sinew and melt-in-your-mouth tender meat, I would be able to enjoy steak without stress.It was a lot of work to develop this knife, but now that we have it, we have raised the level of our technology,” says Kawamura.Kawamura’s words are true, and the “Nami” is extremely popular, with customers waiting several months to obtain a copy.In addition, Kawamura has been developing products that fit modern life, such as a kitchen knife that remains sharp even without sharpening, and a bread knife that can easily cut both soft, high-quality bread and hard bread, in response to the fact that many families do not sharpen their kitchen knives.Although the Japanese sword has been replaced by kitchen knives, craftsmen who can cut with their brains and knives that cut well will always be valued.