There is a phrase, “touching the kin-sen,” which means to be moved by something and have one’s heart tremble. The Japanese people have long compared the emotional response of being moved by something to the beautiful sound of the strings of the koto, or Japanese harp. In Shiga Prefecture, there is the only company in Japan that continues to produce the strings for Japanese musical instruments, which produce such delicate tones, using traditional techniques that do not involve the use of machines. The company is Marusan Hashimoto Corporation, which has a history of over 100 years in Nagahama City.

Making Japanese musical instrument strings started in a silkworm-raising village in Shiga Prefecture.

Marusan Hashimoto Co., Ltd. is located in Nagahama City in the northeastern part of Shiga Prefecture. Blessed with high-quality water from the foot of Mount Shizugatake, the city has been engaged in sericulture and silk spinning for more than 1,000 years.

In the past, the strings used for Japanese musical instruments such as the koto (Japanese harp) and shamisen were all made of silk. The “namabiki” method of thread-making, which has been handed down in the Oto district of Nagahama City, is said to have taken root in this region because it was particularly suitable for making the strings for Japanese musical instruments, which require great strength.

Produces over 400 types of strings

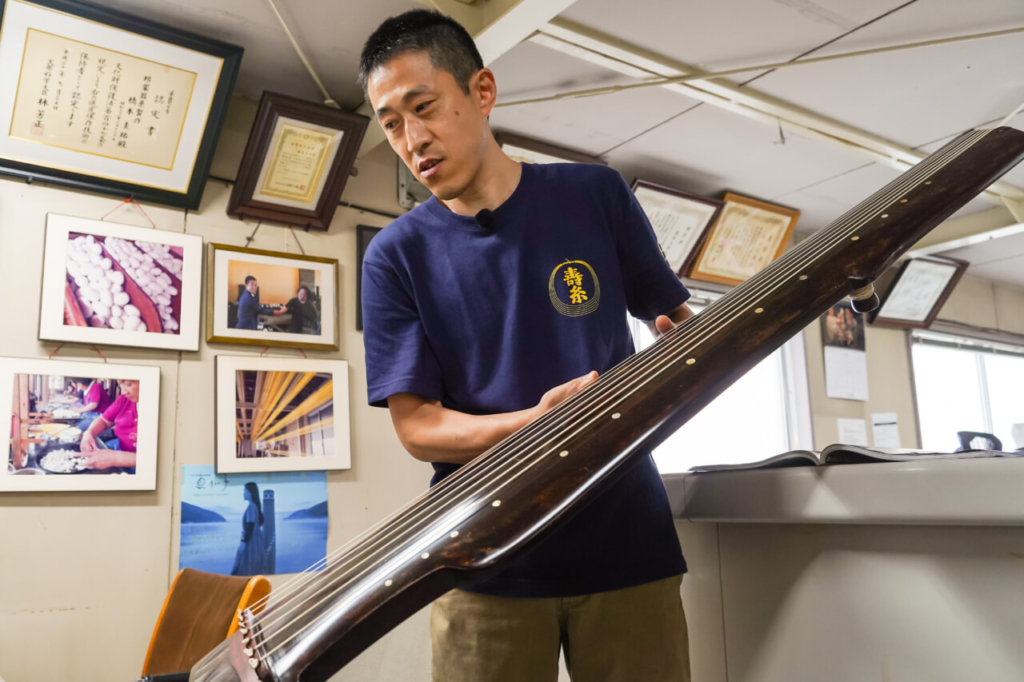

About 120 years ago, my great-grandfather learned how to make strings for the gidayu shamisen, which was popular in Osaka at the time, and returned to Nagahama to begin making strings for Japanese musical instruments,” says Hidemune Hashimoto, the fourth-generation owner of Marusan Hashimoto Co. Since then, the company has produced more than 400 types of strings for Japanese instruments, according to the thickness of the strings, type of instrument, and rank, while focusing on the strong and deep sound that only the company can produce.

For example, our shamisen strings are used at the Kabuki Theater in Tokyo and in Bunraku ningyo joruri (puppet theater), a classical performing art in Osaka,” says Hashimoto. In particular, the company boasts an almost 100% share of the professional market for gidayu shamisen, an essential part of ningyo joruri bunraku (puppet theater).

Only three companies in Japan continue to produce silk strings

Silk strings used to be the mainstay of Japanese musical instruments, but due to food shortages during and after World War II, mulberry fields, which provided food for silkworms, were converted to fields and rice paddies. The rapid spread of polyester threads also made it common for the strings of Japanese musical instruments to be made of synthetic fibers. Nowadays, more than 95 percent of the strings used for the koto are made of polyester. Silk, a natural material, is inevitably susceptible to moisture and breaks easily, so it seems to be shunned today, when durability is more important. However, there are still many people who demand silk for shamisen and biwa, so we continue to make them while maintaining the traditional production method,” he says. Currently, there are only seven companies in Japan that make strings for Japanese musical instruments, and only three of them are still producing silk strings.

The only company in the world to inherit the “Dokuraku Twisting” technique

Of the three companies that continue to produce silk strings, only Marusan Hashimoto has inherited the “Koma-yori” process. In this process, several thin raw silk threads drawn from cocoons are twisted together to make a single string. The key point of this process is that the thin threads are not just gathered together, but twisted as they are twisted together.

Normally, the dokuraku twisting is done by three people: one person stretches the thread by running a distance of about 16 meters, while the other two twist the thread by spinning the dokuraku with a board held in both hands. The work is hard, requiring the workers to sit on their backs and use their legs to twist the strings. It is said that it takes 10 years to become a full-fledged craftsman.

“Japanese sound” transmitted through traditional techniques

In string making, the stronger the twisting, the thinner the string with fewer gaps between the fibers, and the fewer the twisting, the softer the string with more air. The strength and method of twisting have a direct effect on the tone of the instrument.

In the past, when there were no machines, everything was twisted using the Dokugaku method, and we are the only company in Japan that still uses this method. We are the only company in Japan and probably the only company in the world that still uses this method. When twisted by machine, the twisting is too strong, resulting in a choked sound, but when done by hand, a slight space is created in the yarn, allowing the sound to fly far, even in a large hall. The sound from the instrument spreads randomly through the air, which sounds very comfortable to us Japanese,” he says.

Selected for a project to restore a one-of-a-kind treasure

The Dokugaku twisting technique attracted particular attention in 2011, when work began on the reproduction of a raden sandalwood five-stringed biwa, a five-stringed biwa in mother-of-pearl inlay. The raden shidan five-stringed biwa is a musical instrument of Indian origin believed to have been made in the Nara period (710-794), and is a unique treasure representing the Shosoin Repository. The Imperial Household Agency decided to make an elaborate replica in order to clarify the production techniques of the time, and Marusan Hashimoto was selected to make the strings. Usually, Dokugaku twisting is used to make thin strings for shamisen and other instruments. To make thicker strings for the biwa, he prepared a 1.5-kilogram Dokugaku, which is not usually used, and spent four months perfecting the strings, paying careful attention to the thickness and direction of twisting. During the production process, I felt as if I was talking with the people who made this biwa a long time ago,” he said. The technique that has been passed down through the ages for more than 1,000 years is now in my hands. It gave me a chance to rethink my desire to preserve this technology and the sounds it produces.

To preserve the culture and the tone that has been nurtured in the region

In the old days, there were many companies like ours making strings all over the country, and each culture, such as Edo, Kamigata, and Kyushu, had its own distinctive sound. For example, in Kamigata, a bright and relaxed sound is preferred, while in Kanto, a solid and hard sound is preferred. Local string makers produced the sound of their region, but now there are only a few makers left in the country,” he says. The existing manufacturers inevitably understand and reproduce the sounds of other regions. In response to a wide variety of requests from professional players, such as “I want a more shadowy sound,” “I want a sound that falls into the back,” or “I want a rounder sound,” the sound of that region or school of music is reproduced. Mr. Hashimoto says that the most difficult thing of all is to find out how to incorporate this into the manufacturing process to achieve the target sound.

Until about 10 years ago, he had been making strings only for Japanese musical instruments, but now he is turning his attention to the world. He has been making strings for a variety of instruments, including ukulele strings, which he became interested in when he met a musician, the Korean “haegeum” xiqin, and the traditional Chinese “kokin” instrument.

In 2011, we participated for the first time in an exhibition in China, and although there were about 1,800 booths, we were the only company that exhibited with silk strings. In China, where silk strings have been used for over 3,000 years, steel strings are now the mainstream. Silk was introduced to Japan via the Silk Road, and now we want to pass it on from Japan to China. When I said this while showing pictures of the Silk Road, everyone was very happy. Mr. Hashimoto happily says that the whole of Asia becomes a family when silk strings are used. Knowing how to make traditional strings, the history of the instruments, and the tastes for sound in other countries will probably deepen his knowledge of tones that are unique to Japan.

Pursuing the value of “sound” as a string manufacturer

From 2022, Mr. Hashimoto also serves as vice president of the National Federation of Traditional Japanese Musical Instruments Associations. He hopes to engage in activities that will encourage people in Japan to pay more attention to Japanese traditional musical instruments. As an industry, it is obvious that we are tapering off if we don’t do something about it. The silk strings we make are not only rare in existence, but also have great value as an invisible “sound. I believe that if more people appreciate the sound, the value of preserving them will increase.

These days, the opportunities to hear the sound of silken strings have been drastically reduced. Why not experience the “real” sound while paying attention not only to the music and the performers, but also to the manufacturers behind the music?