A hometown of Japanese paper, Ogawa-machi

Ogawa in Hiki-gun, Saitama Prefecture is famous for Japanese paper. Especially, ”Hosokawa paper” which is thick and durable, is designated as Important National Intangible Cultural Property. The history is not exactly known, but one theory has it that the origin goes back about 1300 years.

It developed into an industry in Edo period. Being near the city of Edo which had a population of more than one million, the paper making industry was established there, as the demand for paper went up. More people meant more demand of paper makers in Ogawa studied various kinds and forms of paper from all over Japan, and developed skills enabling them to produce all kinds of paper.

Paid tax by paper!?

According to Takamasa Kubo of Kuboseishi, who showed us around, there is other reasons why, paper making industry became active in Ogawa.

One reason was, there was an abundance of ”kouzo” or paper mulberry, the main material for paper. The plant has very strong roots, so it was planted abundantly to reinforce soil. In the mountains surrounding Ogawa-machi, many ”kouzo” trees were planted to hold the soil to dam up water. Paper making started using these ”kouzo” trees.

Another reason was, the tax was paid by paper. ”In those days, there was not enough rice or other farm products to pay tax. So people paid tax with paper. It is believed that this led to further development of paper making industry,” said Kubo. Demand, availability of material, and tax, these elements have lead to the development the local traditional industry.

Why wouldn’t wet paper stick together?

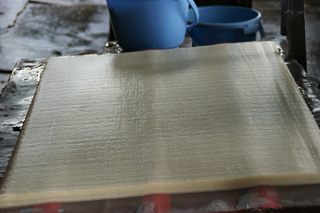

In the workshop, Haruo Kubo, the manufacturing manager of Kuboseishi showed us the process of paper making. He worked with a large wooden frame called ”sukigeta”, which he rocked back and forth. This process is something one would imagine by the phrase traditional paper making . Of course, it is not easy as it looks. It requires well trained skills.

Nakata had a try, but he had to struggle very hard, since it was difficult to make an even sheet of paper in the ”sukigeta”. Then the sheets of paper are stacked carefully one by one. Then Nakata asked, ”And the wet sheets of paper don’t stick together, do they?”

”That’s right. By rocking, and straining water, the fibers of paper lie flat, so they don’t stick together. When these processes are skipped, the fibers become rough, and they stick together.”

That means each sheet is already a finished product. The stacked sheets are then squeezed and finally dried.

At Kuboseishi, they make a wide variety of paper, such as plain Hosokawa-gami, or paper with texture or dyed paper. In Japanese living style, there still is a lot of paper used in our surroundings, such as ”shoji (paper screens)” and ”fusuma (paper doors)”. I am sure that you will want to be more familiar about Japanese paper, when you get to know the traditional paper making.