Senkanshi” has been handed down in the mountains of Nomura-cho, Seiyo City, Ehime Prefecture since ancient times. This paper has been valued by court nobles and samurai families in Kyoto and Edo (present-day Tokyo) for its toughness made by a unique technique. Kikuchi Seishi is the only paper maker in Japan that continues to preserve this tradition. Today, the workshop is run by Takashi and Kensuke, father and son. In the midst of abundant nature, the one-of-a-kind technique that has been passed down from generation to generation is being passed on to the future.

Strong washi born in a mountain village in Seiyo, Ehime

Ehime Prefecture has long been a center of the papermaking industry. This is due to the abundance of water and the abundance of kozo (paper mulberry) and mitsumata (mitsumata), the raw materials used to make washi. Nomura Town in Seiyo City is no exception. Located in the mountains and blessed with clear water, the town has long nurtured a culture of papermaking.

The history of Izumi-Kanagami dates back to the Azuchi-Momoyama period (1586-1597). It is said that Tarouemon Hyodo, commonly known as “Senkaishi,” invented thick, strong paper by overlapping two sheets of paper during the papermaking process. This strong and flexible paper was useful for a variety of purposes, including sutra books, dyeing patterns, tatami mats, papier-mâché, and folding screens.

This process was taught to farmers, and during the Edo period, it spread as a side job during the off-season. As a way to survive in the area, people harvested kozo (paper mulberry), cooked kozo using a rice-cooking pot, and made paper.

It developed as a local industry during the Meiji period (1868-1912), and boomed from the Taisho period (1912-1926) to the early Showa period (1926-1989). However, demand for washi declined sharply over time. Combined with the spread of postwar paper, by 1968 there was only one paper manufacturer, Kikuchi Paper Mills. Sixty years later, Sadashige Kikuchi, the sixth generation of Kikuchi Paper Mills, passed the baton to Takashi, the seventh generation, and Kensuke, the eighth generation, joined him to carry on the tradition of “Izumi paper.

The tradition has been handed down by the decision of the 6th generation. The only company in Japan that continues to protect Izumi paper.

It is mid-March, a morning in a mountain village still bitterly cold. In the workshop, filled with clear air, were Takashi Kikuchi and Kensuke Kikuchi, father and son.

Takashi is the seventh generation of the Kikuchi family to run a handmade washi farm. When I started Izumi-Kanagami, I was just following in my parents’ footsteps and helping them,” he says modestly, but like his father, Sadashige, he has been recognized as a “Contemporary Master Craftsman.

Kensuke, the 8th generation, left for Osaka after graduating from high school, but returned home in May 2013. Until then, he had worked in a completely different industry, such as apparel, and had no experience in papermaking.

However, the turning point came in 2012. When I returned to my hometown for a friend’s wedding, I saw my father making paper and felt that I had to carry on the craft,” he says, deciding to join the family business at age 25. He decided to join the family business at the age of 25. “I thought I could do it because I was still young, but it was a lot harder than I expected,” he says with a laugh.

After the war, demand for washi declined sharply, partly due to the spread of paper. Many families quit, partly because papermaking was a sideline business to begin with. While everyone around him was devoting themselves to their main business of farming, my grandfather did the opposite: he quit farming and made paper his family business. Without this decision, Izumi paper might have already ceased to exist,” says Kensuke.

Because of its rarity and traditional value, Izumi currency paper is also designated as an “intangible cultural asset that should be recorded and other measures taken.

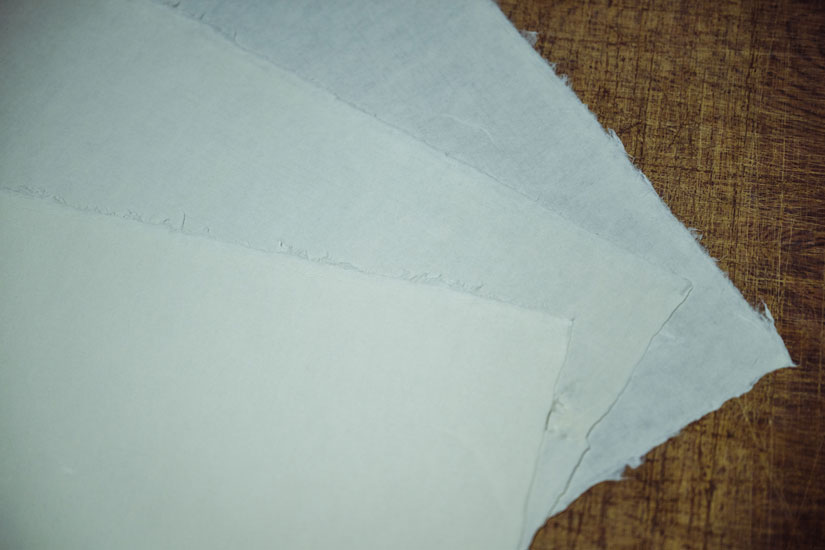

The secret of the strength of Senka-gami: the art of combining two sheets of paper

The most distinctive feature of Senka-gami is its two-ply lamination process. There are six cells in the bamboo frame for making paper, and the front three cells are covered with thick bamboo screens, and the back three cells are covered with fine bamboo screens. The coarseness of the bamboo screen in papermaking greatly affects the thickness and texture of the paper to be made. The coarse bamboo screen is easy to make thick paper containing a lot of fibers because water passes through well, and the fine bamboo screen becomes a thin and smooth paper surface because water does not pass through well and fibers are easily dispersed uniformly. By making these two types of paper at the same time and then layering them together, the paper is made even stronger than before. The paper is so tough that it is even used for the paper garments used in the Shuni-e (water-drawing ceremony) at Todaiji Temple’s Nigatsudo Hall in Nara.

The materials used are kozo (paper mulberry) and tororoaoi (mallow). Kozo, which has long been used as a raw material for washi, has thick and long fibers that are easily entangled, making it suitable for making strong washi. Neri, a mucilage extracted from the bark of the root of the tororoaoi, also serves as a natural glue. It is indispensable in the papermaking process to ensure an even spreading of the kozo fibers.

The mixture of kozo and neri is pumped into a bamboo frame, and the fibers are entangled and the thickness of the paper is matched through a delicate repetition of vertical and horizontal shaking. This delicate shaking is truly a craftsman’s skill and depends largely on the sense of the craftsman.

It is important to match the two sheets of paper immediately after they are finished. The fine mesh in the back is lifted up, and the paper in the front is made into one sheet by aligning it exactly with the paper in the front so that air does not enter. The matched papers are pressed to remove water, and then placed on an iron plate heated to 70 to 80 degrees Celsius. The paper is then dried by stretching it with rollers to complete the process.

The secret of good papermaking is to let nature take its course. That is the secret of good papermaking.

Although the papermaking process has an image of being done during the cold season, it is now possible to make paper throughout the year by using preservatives to prevent the water from spoiling. However, the best washi is made from winter to spring. Kikuchi Paper Mills draws water from the river, so the water temperature is extremely cold. This coldness is essential to the papermaking process.

The cold water is essential for the papermaking process. That’s why we have to test our patience in the winter,” laughs Takashi.

Although chemical glue is now commonly used as a substitute for Trolloa, he always uses Trolloa when making Izumikurigami.

Compared to chemical glue, the glue is smoother. When making fountain currency paper, chemical glue sticks to the paper unnaturally, and for fountain currency paper, which is made by overlapping two sheets of paper, tro-aoi is the best choice,” says Takashi.

Procuring the tools used for papermaking is not easy either. In particular, it takes six months to a year to complete the delicate bamboo screen made of woven bamboo and silk twine, because the number of craftsmen is decreasing. However, a good bamboo screen is straight and beautiful, and it does not warp at an angle. This is a condition to produce good paper.

It is adopted for the restoration of prints and paintings. Washi recognized around the world

The main demand for Senkanshi is for printing paper for overseas markets. Unfortunately, local demand is low, with the majority of demand coming from outside the prefecture and overseas.

In recent years, in particular, demand from overseas has exceeded domestic demand as washi is increasingly being used in European museums to restore paintings and works of art.

Japanese washi has long been valued for its fine texture, thinness, and uniform weight, but the strong and supple characteristics of Senkanshi paper and its ability to produce different textures on the front and back sides due to the combination of two sheets of paper with different textures are also gaining support.

Kikuchi Paper Mfg. ships as many as 3,000 sheets of fountain currency paper to overseas markets every month. This is proof that Japan’s traditional crafts are attracting attention overseas.

A Mission for the Future and New Challenges

While there is certainly demand for Izumi-Kunagami, it also faces challenges such as the rising cost of raw materials, labor costs, and unit prices. A single workshop cannot form a cooperative, and it is difficult to obtain support from the local government.

Takashi says, “I don’t want the Izumi paper technique to die out in my generation. We just have to keep going,” says Takashi.

Kikuchi Paper Mfg. has begun to take on new challenges while preserving the tradition of Senka-gami. One of these is the development of processed products that take advantage of the wrinkles and debris that occur during the manufacturing process. The company aims to expand its sales channels and create a sustainable system that enables the producers themselves to generate profits.

Kikuchi Paper Mills also accepts overnight farm stays, and school excursion students from Tokyo come to stay for the experience. The high school students make postcards and take them home with them, a valuable experience that they cannot have in the city. The experience of being soothed by the murmuring of the river and coming into contact with the one and only Izumi-Kanagami will be a special time for them. Furthermore, every year, children from the local Nomura Elementary School visit the mill as part of their class, contributing to the learning experience of the local community.

The future of Izumi-Kanagami lies in the passion of Takashi Kikuchi and Kensuke Kikuchi and their challenge to create new values while preserving tradition. We hope that this washi, nurtured in the mountain villages of Seiyo, will continue to attract many people with its strength and beauty.