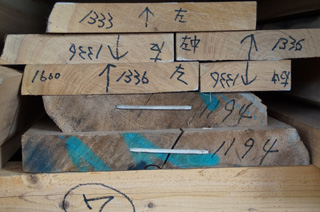

Wood storage lined with lumber

Our meeting point was a wood storage site named ”the broad leaf tree forest”. It is a furniture making company, but they wanted us to see the lumber first. Inside the storage, they kept huge strips of wood in sizes that we have never seen stored as material wood. Kota Kudo told us something quite shocking as he showed us around.

”To tell you the truth, all the broadleaf trees in the Japanese national forests are completely harvested.” The trees that are in the storage room were all bought more than 30 years ago. When you are making furniture that requires one huge piece, you need a big tree. However, Japanese market for broadleaf tree is declining, and it is difficult to find such a huge tree. One of the reasons is that imported wood is available on the market, and in the national forests of Japan, they had encouraged planting conifer trees since they are believed to grow faster.

One tree grows for 100 years and becomes the value of a mountain

”People who owns a mountain will cut down the trees once every few years in order to produce pulp. However, it’s actually better to leave 10 to 20 good broadleaf trees, rather than to harvest all the trees. The trees that remain for 100 years time which is 3 generations, will grow big and it will be worth one mountain in value. It is important to keep those good trees.”

Nakata was surprised to hear this and said, ”You are taking that much time and thinking about everything for the long term.” It certainly takes time for a tree to grow. You have to deal with trees and think on that scale of time.

Then we came to a huge tree outside that is over 6 m long. We were specially allowed to to see the process of making this tree into wood material. They process the wood watching for the ”core” that every tree has, and how it is placed in the tree.

”It seems really difficult to teach this technique or the feeling”, said Nakata. Kudo replied ”You cannot be taught to process wood. It is experience. You need to ask the tree and learn from them.

The destiny of the tree

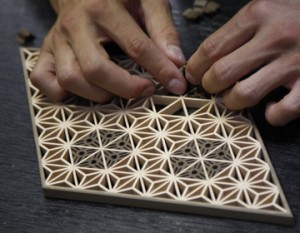

Iwaizumi Junboku Kagu does everything themselves from collecting trees to processing the wood and then making the furniture. At the processing factory, Kudo said ”Ask the tree and learn” but the it’s the same in the furniture factory.

”When we make our furniture, we wish to question the tree and then design. We can imagine what can be created only after observing the original wood.”

After the furniture is finished, we look at it and think, ”This tree was destined to be this way.” That is the moment when they are really happy. The furniture is finished with oil lacquer. They make the furniture centered around the wood without using a single nail. They converse with the tree during the process of making a wooden board from lumber. And they converse with the wood ”what kind of furniture do you want to be?” In order to reach the state where you are totally convinced that ”this tree was destined to be this”, one must truly come to terms with the tree.