Kannon Sui,” selected as one of the 100 best waters in Japan, springs in the Akanma district of Uwa-machi, Seiyo City, Ehime Prefecture. In this area, where the original Japanese landscape still remains, washi designer Yukari Sato is pursuing new possibilities for washi by taking advantage of the blessings of pure water. By combining traditional handmade washi techniques with digital technology, she has created unprecedented three-dimensional washi works.

From the 350-year-old production center of Ozu washi

Mr. Sato hails from Igasaki, Uchiko-cho, Ehime Prefecture, known as the birthplace of Ozu washi, a traditional handmade paper. Ozu washi is said to have been established in the Genroku era (1688-1704) by the Ozu clan, which invited Echizen washi craftsmen to establish the technique while enjoying the benefits of the clear Oda River. By the end of the Meiji period (1868-1912), there were more than 400 craftsmen, but with the spread of western paper, the number of craftsmen has been reduced to a few in recent years, making it a challenge to pass on the traditional industry.

After graduating from high school, Ms. Sato left her hometown and worked as a model in London. While busy with her work, she was informed by her father that the local handmade washi industry was in a difficult situation.

I knew I wanted to work with washi eventually, so after returning to Japan, I studied design at the Kuwasawa Design School in Tokyo. During my sophomore year, my father’s construction company decided to start a project with the Ehime Prefectural Institute of Industrial Technology to produce washi for construction, and I was asked to participate as a designer.

Feeling a positive response to the challenge of product development while traveling back and forth between Tokyo and Uchiko, Sato returned to his hometown in 2010. In 2010, he returned to his hometown and began to produce washi in earnest in his hometown.

Delicate and light. The Birth of “Breathable Washi

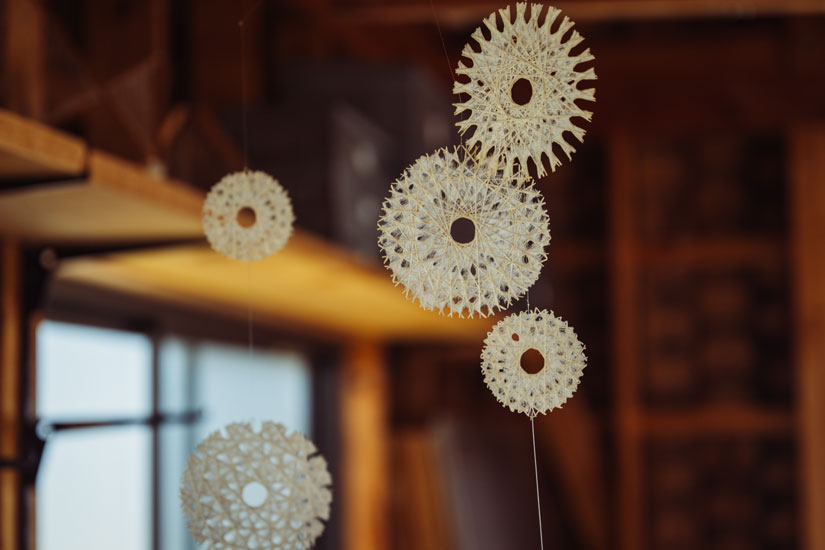

The project launched by Mr. Sato’s father and others resulted in washi made by attaching zeolite, a mineral, to kozo (paper mulberry), the raw material for washi. It is called “breathing Washi” because of its high humidity control and deodorizing functions. Mr. Sato found a way to utilize the characteristics of this paper in interior decoration and created mobiles to hang in living spaces. The idea originated during his time in London. He often saw buildings in London with high ceilings and interiors that took advantage of the blank spaces. The idea of having interiors like mobiles in Japan took shape.

First, a wooden frame is made by weaving twisted Japanese paper threads like lace around a wooden form with studs, and then gluing it together. Zeolite kozo (paper mulberry) is then manually strained into the frame to create the shading of the kozo fibers. This is an original technique that follows the traditional papermaking method while taking advantage of the suppleness and beauty of zeolite washi.

Looking around the workshop, where a huge water tank for making paper is placed, one sees mobiles hanging from the ceiling. The mobiles swaying in the wind are delicately beautiful and have a lightness that overturns the conventional image of washi.

A workshop in a mountain village blessed with famous water

In 2012, Sato moved from Uchiko Town to Akema, Uwa-machi, Seiyo City, where Kannon Sui, selected as one of the 100 best waters in Japan, springs, and opened the Rikuu washi studio on the site of his grandparents’ house.

It is said that the Kannon Sui is said to have been produced by rain that fell on the Shikoku Karst during the Edo period, becoming underground water that welled up from a cave, bringing a blessing of 8,000 tons of water every day to the Akema area where the workshop is located. The water is said to be ideal for handmade washi because it contains few impurities, and it is said that paper making used to be prosperous in this area.

He built a workshop in his garden and created an environment for making washi by drawing Kannon water. Sato’s works fit in well with the home he inherited from his grandparents. Zeolite washi, which is slightly translucent and even fragile, does not feel oppressive, even when used in large objects such as an impulse stand, and creates a light and airy feeling in the space.

3D digital technology opens up new possibilities for washi

Washi paper is being phased out in today’s living environment. However, its delicate beauty, softness, and warmth should remain close to the hearts of Japanese people throughout the ages. With the support of her husband, Tenshi Terada, who is a 3D modeler, Sato is taking on the challenge of creating products that actively incorporate new technologies, such as digital fabrication, as a way to convey the appeal of washi to the modern age.

The workshop is decorated with mobiles, lighting, and interior accessories, some of which are co-created with Ms. Terada. 3D digital technology is used to create three-dimensional washi paper products. 3D modeling is used to create the parts, and the three-dimensional objects are then made using techniques developed through experience.

Mr. Terada is also involved in a project to use a 3D printer to produce Awa Ningyo Joruri (puppet theater) in Tokushima Prefecture, which is designated as an important intangible cultural asset by the Japanese government, and has a deep understanding of the fusion of traditional crafts and digital technology.

He has a deep understanding of the fusion of traditional crafts and digital technology. “Until now, most three-dimensional washi works have been organic in shape and have a massive image, but by utilizing 3D digital technology, it is possible to create lighter, more modern designs,” he said. The range of expression of washi has expanded,” they say in unison.

Mr. Sato comes up with the idea for the design, and Mr. Terada performs the simulation on the computer. The studio is equipped with a 3D printer, laser cutting machines, and other digital fabrication equipment, and a series of processes, from modeling to handmade paper, are completed in the lab.

The difficulty level of handmade washi increases when it comes to three-dimensional paper, especially when it comes to curved surfaces, but he certainly feels that there is room for further exploration, such as devising new ways of placing zeolite Kozo fibers on the paper. Mr. Sato and the washi craftsman with whom he works spent about five years developing a unique technique for coating washi in a mousse-like texture.

Washi paper shows various expressions by adding undulations and twists.

Rikuu’s signature product is “Hineri,” a washi paper lighting system that utilizes digital technology to create joint parts that connect wooden frames using 3D modeling to create a complex design with a real twist.

Sato, who has been exposed to the world of interior design, design, and fashion overseas, brings out new charms in washi with his unique sensibility.

Digital technology as a new tool

Some people may worry that incorporating digital technology into traditional crafts will take away from the traditional techniques. However, we see digital technology as one of the tools of the modern age. We imagine a manufacturing process that incorporates the latest technology into the handcrafted production process and takes advantage of the strengths of each,” says Sato.

His innovative designs, which open up new possibilities for the expression of washi, have been highly acclaimed both in Japan and abroad, and orders from hotels and luxury brands are pouring in one after another. He has been involved in a wide range of client work, including lighting for RIMOWA’s Omotesando store, decorations for Louis Vuitton stores in Japan and abroad, and artwork for the InterContinental Yokohama Pier 8.

New products utilizing local materials

While working to integrate with digital technology, the company is also actively engaged in returning to its roots. One such effort is the revival of handmade washi using local kozo paper. In recent years, the company has increasingly relied on Southeast Asia and other overseas sources for raw materials, but the Onikita Senkanshi Preservation Society, with which the company cooperates in the production of its works, is now trying once again to collect locally grown and propagated kozo, which they call “Iyo kozo,” and use it as a raw material. By using unbleached paper in accordance with the old-fashioned production method, the original characteristics of the kozo are preserved, giving the paper a simple color, silky luster, and unique texture.

At the same time, Mr. Sato also paid attention to Iyo Raw Silk, a precious domestic silk produced in the neighboring town of Nomura, Seiyo City. As a result of his search for effective use of cocoons, which are out of the standard cocoons used to make Iyo silk, a product called the “White Camellia Aroma Diffuser” was born, using Iyo cocoons and Iyo kozo (paper mulberry).

A 3D printer is used to create a mesh base in the shape of a camellia, and Iyo Kozo is used to make the base.

The center of the diffuser, into which the aroma oil is soaked, is made of cocoons, the source of Iyo raw silk.

To connect traditional crafts to the future

While maintaining respect for the ancient techniques and materials used to make Japanese paper, Mr. Sato’s challenge is to fuse them with cutting-edge digital technology.

He hopes to continue to expand the possibilities of washi by mixing various materials and preserving the traditions while continuing to innovate.