Creator of the beautiful and gentle white “White Mud Oshima”

Many people may think of Oshima tsumugi as beautiful black or dark blue fabrics produced through a chemical reaction between the iron in the mud and the tannin in the dye. However, Mr. Yukichi Masuda of Kagoshima City is an Oshima pongee artist known as the creator of “HAKUDEI OHSHIMA,” which overturns such conventional wisdom. The white silk kimono hanging in his workshop is beautiful with its pale and mellow white tone and detailed patterns. Most of the white Oshima produced by Mr. Masuda are original designs. Most of the white Oshima produced by Mr. Masuda are original designs, created to suit modern sensibilities, and there are few so-called classic patterns.

The white Oshima is not pure white, but has a beautiful, delicate coloring. It is a milky white, or a gentle white like porcelain.

That is exactly the starting point. Oshima tsumugi uses the same mud as Satsuma-yaki, a ceramic ware, but there are black Satsuma and white Satsuma in Satsuma-yaki. I thought that the white color of Oshima tsumugi could also be made with mud, so I continued my research,” says Masuda.

Mr. Masuda is from Kikai Island, located east of Amami Oshima, and when he was 21 years old, he started working for Kei Oshima Tsumugi Textile and became involved in the development of white mud-dyeing technology. He spent many years researching to produce beautiful white Oshiman Tsumugi silk, which inherited the softness and gloss peculiar to mud-dyed Oshiman Tsumugi, and developed the white mud-dyed Oshiman Tsumugi silk. In 1984, Mr. Emi Michio registered the trademark of “Hakkeidoro” under the name of “Hakkeidoro” and Megumi Oshima Tsumugi Textile closed its business, so the trademark of “Hakkeidoro” was inherited by Mr. Masuda.

To know all about Oshima Tsumugi

Before Mr. Masuda started the white mud dyeing process, there were Oshima pongees that were whitened with chemical dyes, but this did not give them the moist, supple feel and color that are the characteristics of mud dyeing. Shirae mud is the white clay of white Satsuma porcelain. It takes about two months to thoroughly remove impurities from the mud particles that have been formed over tens of thousands of years before dyeing the yarn. By doing so, the fine mud particles penetrate deep into the threads of the cloth, and each thread is slightly aerated, creating a fluffy texture. By not dyeing, the threads are resistant to fading, yellowing, and friction, and they recover from wrinkles quickly. The deep off-white color with reduced luster is a unique color that can only be produced by the power of nature.

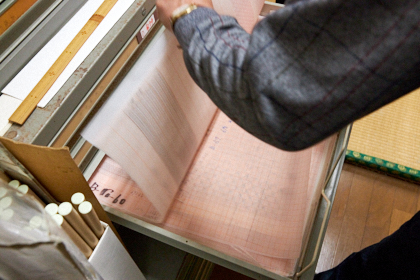

Today, most Oshima tsumugi is made at major factories, where the division of labor from design to dyeing and weaving is the norm. However, Mr. Masuda does everything himself. In the back of his ordinary home, there is a workshop for dyeing and a weaving machine.

It took me nine years of searching for the right color before I found it,” he says. It’s hard to work alone, but that’s why it’s so interesting. But that is why it is so interesting. It has long been said that craftsmen rely on experience and intuition, but it is also important to gather data. There are many things to be learned from traditional techniques,” says Masuda.

Dyeing alone is hard work, but Mr. Masuda’s weaving technique, which uses the remaining kasuri threads in the design, is also very detailed and time-consuming. It is like creating a puzzle from a huge number of pieces. Even so, Mr. Masuda continues to work at it day after day.

He has never been satisfied with his work. I want to make better Oshima silk,” says Mr. Masuda.

He has a big smile on his face as he talks about this. I have learned that a person who has found a job to devote his/her life to can look so good.