Shoe Brand ”Guild”, Supported by Numerous Fans

Guild uses the hand sewn, welted construction method. It is a leading manufacturing method that has a history of several hundred centuries. The insoles are thick and firm, the structure is sturdy, and the shoes can be resoled many times. Imported leather shoes from Italy and the U.K. are popular, but even in comparison, Guild shoes have ranked high, placing first and second in a magazine ranking based on popularity.

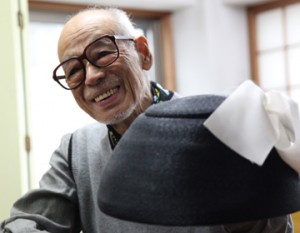

We spoke with Chihiro Yamaguchi, the representative of Guild. Yamaguchi not only runs the company, but is also a craftsman. He flew to the U.K. when he was 27 and studied at a school specializing in shoes. There, he obtained the certificate, Shoes Pattern Level 1. The following year, he was awarded ”Guild of Master Craftsman”, the very first for a Japanese. After returning to Japan, he worked as a designer and in 1996, founded Guild.

Constructing Shoes is as Complex as Constructing a House

Do you know how many steps are involved in making a pair of shoes? The majority of people probably don’t know the answer, because most only know about off the shelf shoes. Most people do not know how the soles of shoes are made, or how the leather is sewn together. Even Nakata, who has special ordered many pairs of soccer shoes, knew very little about the shoe making process. When Nakata asked how many steps were necessary to create a single pair of shoes, the response was ”as many as constructing a house”.

It is said that there are more than 100 steps to construct just one pair of shoes. Of course the precise number is difficult to pinpoint, since each customer’s needs are different. In addition to taking measurements and picking out a design, there may even be a need to consult a foot specialist or a podiatrist. In addition sewing or even hammering may be necessary depending on the material.

First you listen to the client to find out what of house he wants, you draw a blueprint, order the materials, and finally start construction. Shoe making is just the same as constructing a house. After going through all the steps, you finally have that one of a kind pair of shoes, with a unique design, material, and size.

Why Handmade?

Nakata inquired why the emphasis on creating shoes by hand, when it required such complex skills as well as time. ”Simply put, because I can make shoes that ”fit your feet”. It will fit perfectly. If it is handmade, the right and left shoe doesn’t have to be the same. This can’t be done with ready-made shoes. Manufacturing just one pair doesn’t make sense, and things that cannot be made by machines can make people happy.”

Nakata commented about difficult it is to find a pair of shoes that really fit. Yamaguchi told us, ”If you become accustomed to wearing uncomfortable shoes, it’s difficult to understand what it’s like to have good fitting shoes. Once you encounter shoes that fit, it will stimulate a desire for more. A desire for more comfort. You become aware of the details that require attention. Then, we try to respond by making minute alterations. It’s very hard to get a perfect fit on the first try. That’s because it is a journey that the customer needs to be involved with as well.”

What you want in a pair of shoes depends on the person. Some people will compromise comfort as long as the shoes have a beautiful silhouette, and for others, comfort is of the utmost importance.

Yamaguchi talked about the importance of ”discussing” exactly what the customer`s priorities are. ”You spend more time in your shoes than in your bed, so customers can be quite harsh with their feedback. No matter how beautiful a pair of shoes turn out to be, it’s very sad if they are not worn. To avoid this from happening, we need to really understand the customer’s preferences. We all feel greatly relieved when a customer comes back to order their second pair.”