IKEUCHI ORGANIC, a globally recognized Japanese brand of Imabari towels, takes a unique stance in the production of safe and environmentally friendly towels. 70 years after its establishment, the long-established company’s creative approach is based on the strong belief of its representative, Keiji Ikeuchi. The Imabari Factory Store was renovated from the factory where the company was founded, which is also the company’s starting point.

What is “Imabari Towel” again?

Towels were introduced to Japan from Europe in the early Meiji period. Towel production began in Imabari City, where cotton fabrics had been produced since the Edo period (1603-1867). Since towel production requires a large amount of water, the abundance of water is a prerequisite for the production area. The subsoil water of the Soja River, which flows through the center of Imabari City, is soft and gentle to yarns and fabrics, and brings out the original softness of cotton, which is one of the reasons why Imabari City became a towel production center. Currently, 98% of all towels produced in Japan are produced in Imabari City and Senshu City in Osaka, and Imabari City is a major towel production center with nearly 200 towel-related factories, including twisted yarn factories, dyeing factories, and weaving factories.

Imabari Towel Quality Embodied in the Brand

However, not all towels produced in Imabari City can claim the name “Imabari Towel. Only towels manufactured by the 75 companies of the Imabari Towel Manufacturers Association that meet the strict quality standards set by the association can call themselves “Imabari towels. The most obvious example is the “5-second rule,” which guarantees a towel’s absorbency: when a piece of towel cut into 1 cm squares is floated in water, if it begins to sink within 5 seconds, it has passed the test.

In addition, there are several other strict quality standards, such as pile retention, light resistance, friction, tensile strength, and dimensional change rate, and only towels that have passed all of these standards are called Imabari towels.

Pursuing quality that has been recognized in towel-producing countries since the company’s establishment

IKEUCHI ORGANIC was founded in 1953, and has continued to pursue safety and environmental impact reduction through its commitment to organic production. At that time, bath towels were not yet widely used in Japan, and IKEUCHI ORGANIC began exporting them to the Middle East, Europe, and the United States. In order to produce products that would be recognized in Europe and the United States, the leading towel-producing countries in the world, IKEUCHI ORGANIC made a series of corporate efforts, including the introduction of the latest weaving machines ahead of its competitors, and established itself as a towel manufacturing company specializing in exports.

Keiji Ikeuchi, the current president of the company, became the second president in 1983. Following in the footsteps of his father, the founder of the company, he took on a series of industry firsts, including the introduction of a CAD system, ultra-high speed Jacquard weaving, and computerization. In 1989, the company was also one of the first to be certified under the just-beginning Eco Mark system. Perhaps it was around this time that the fire for the development of environmentally friendly products was lit in Mr. Ikeuchi’s heart.

The foundation of manufacturing is sincerity in quality

High-quality towels have excellent water absorbency and feel soft and dry on the skin,” says Ikeuchi. Towels with good water absorbency can be made by removing impurities and grease from the raw threads, removing glue from the woven fabric to make it easier to process on a weaving machine, and by taking all the time and effort necessary to make each step properly. However, if rationality in manufacturing is prioritized, towels that do not absorb water will be produced.

If you want to make towels softer on the skin, you should unravel the yarns and make them softer to the raw cotton. However, he says that while this may make the towels feel soft to the touch, it also makes them prone to shedding fluff and reduces their durability. Mr. Ikeuchi pursues IKEUCHI ORGANIC’s “high quality” by focusing on the balance between absorbency, comfort, and durability, and by seriously considering the needs of each user.

Rare organic cotton, which accounts for only 1% of the world’s cotton production, is used.

IKEUCHI ORGANIC’s corporate philosophy is “maximum safety and minimum environmental impact,” which is a prerequisite for high quality. Cotton used to be grown organically, but in the pursuit of production efficiency, pesticides and chemical fertilizers began to be used, and the excessive use of these chemicals gradually became a problem. However, because towels are daily necessities, Mr. Ikeuchi came to believe that he wanted to produce the safest towels in the world. Therefore, IKEUCHI ORGANIC now uses only fair trade organic cotton grown from non-genetically modified seeds in fields where no pesticides or chemical fertilizers have been used for more than three years.

The company discloses the traceability of all its products, from cultivation methods in the fields to the spinning process, which is another sign of its honest manufacturing. There are many devoted fans who share this policy, and in the year of the 70th anniversary of the company’s founding, volunteers even placed a poster on the Kyoto Municipal Subway as a surprise advertisement in support of IKEUCHIORGANIC.

Thoroughly reducing environmental impact from the manufacturing process to after sales

The company’s environmental considerations extend to the manufacturing process as well, such as using wind power to supply all electricity used in the company and preparing wastewater from the dyeing factory to meet the effluent standards of the Seto Inland Sea, which is said to be the strictest in the world. This is a reflection of Mr. Ikeuchi’s belief that “clean energy is the only way to produce the safest products possible.

He has not forgotten to consider the environment in the way the towels are used after production. Based on the idea that towels are not consumable goods, but rather beloved items that can be used for a long time, the company is developing permanent standard products and manufacturing products that extend the life of the product.

In addition, the company also provides maintenance services for purchased towels. The company has in-house professional cleaners who maintain IKEUCHI ORGANIC towels brought in from customers at the head office factory, restoring them to a state close to that of the original purchase. They have also supervised the washing machines of a major home appliance manufacturer. All of these efforts are aimed at ensuring that towels are used in better condition for longer periods of time. We are amazed at their solid activities from a broad perspective, rather than just taking environmental measures from a verbal standpoint.

Aiming to create the one and only “edible towel

On the occasion of the 60th anniversary of the company’s founding, the then president and representative director of the company, Mr. Masahiro Nakamura, said, “We will make edible towels by 2073, the 120th anniversary of our founding. This was the goal declared by Mr. Ikeuchi, then president and representative director, on the occasion of the 60th anniversary of the company’s founding. At present, however, both name tags and sewing threads are 99.9% organic. He says that it is difficult to make the threads used for sewing completely organic. We have already achieved this for some of our products, but I think it will take more time to achieve 100% for all of our products,” he said. However, we intend to achieve it for sure,” says President Ikeuchi.

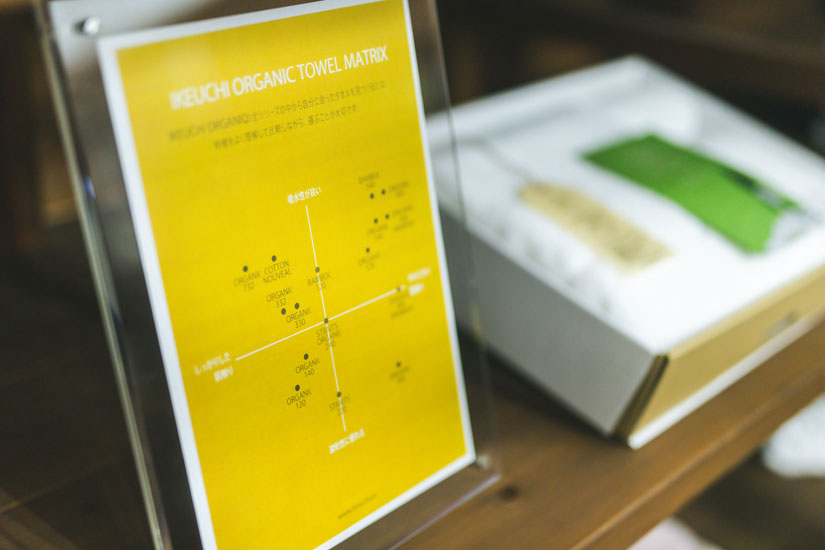

At the “Imabari Factory Store,” which was renovated from the historic wooden building used when Ikeuchi Towel was founded in 1953, there are a variety of IKEUCHI ORGANIC towels of different absorbency, texture, color, design, size, etc. Visitors can actually touch them and ask staff members to help them to see the differences. You can choose the one you like best by touching the towels and asking the staff to help you. The IKEUCHI ORGANIC towels mentioned above are also maintained here. The towels are washed at high temperatures in a special washing machine to refresh them and restore their original softness and absorbency. The high quality and safety of the towels are appreciated as wedding and baby gifts, as well as thoughtful gifts. Visitors can also watch the factory’s looms in action through the windows.

In 2024, “ORGANIC120,” the first organic cotton towel developed by IKEUCHI ORGANIC, won the “Good Design Award” (sponsored by the Japan Institute of Design Promotion). The award was given in recognition of the company’s 25 years of evolution in pursuit of its ideal as a manufacturer, while deepening its knowledge of environmental issues and organic cotton. Towels are used every day. We want to bring the safety of towels up to the level of food, so that people can choose towels as they choose food,” he says.

In pursuit of the ideal of edible towels, Mr. Ikeuchi and IKEUCHI ORGANIC will continue to take on new challenges.